Stainless Steel Technical Guide

Storage and Reconditioning Electrodes

Welding electrodes and wires may be damaged by atmospheric moisture. Figure 38 provides the proper storage conditions, and the time and temperature for reconditioning electrodes and wires that have absorbed excessive moisture. Figure 39 shows an oven used for storage and reconditioning of electrodes.

Pallets and unopened cartons of electrodes and wires should be stored away from exposure to water in the form of rain, snow, spray, or humidity. Only hermetically-sealed cans are safe against these conditions. Damaged cartons permit the entry of damp air which may be picked up by the product and lower its quality.

Low hydrogen electrodes should not be reconditioned more than one to two times, because that may cause a higher moisture absorption rate when exposed to the atmosphere. Over-reconditioning can be as damaging as excessive moisture.

Self-Shielded Wires

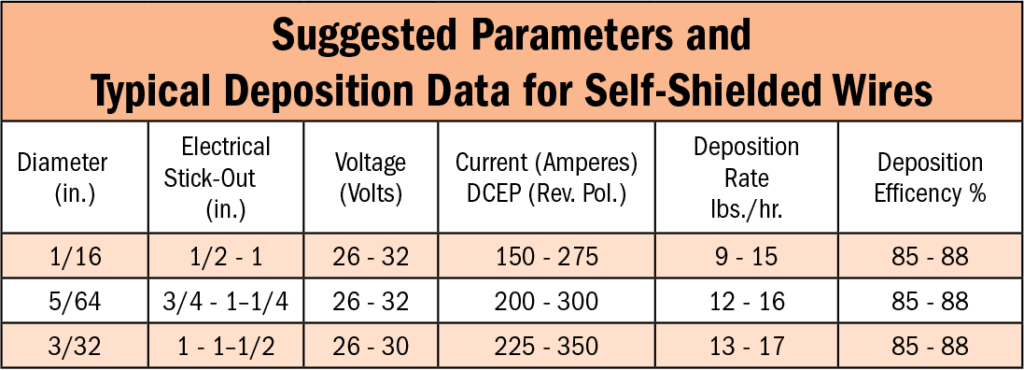

Recommended parameters for self-shielded wires are shown in Figure 40 along with typical deposition rates and efficiency. Loss of ferrite due to pick-up of nitrogen in the arc may be experienced with voltage too high or with current and wire extension too low. These effects are, in general, more pronounced with 3/32 inch diameter wire than with 1/16 inch diameter wires.