Stainless Steel Technical Guide

Ferrite And Magnetic Permeability – Probable Relationship

Producers of austenitic stainless steel filler metals are very aware of the desirability for products that exhibit high operator appeal. However, some applications call for products where “magnetic personality” is a liability and filler metals with low magnetic permeability are required.

One such application is in the welding of hulls and related structures for minesweeper ships. Another is in fusion reactor development where the feasibility of thermonuclear fusion is under exploration. In the latter application, it is critically important that extremely powerful, superimposed magnetic fields be virtually free of uncontrolled perturbation (disturbance or disruption). Hence low magnetic permeability stainless steel is specified for the reactor vessel and associated structures.

What Is Magnetic Permeability?

Gauss and oersted are terms involved in the definition of magnetic permeability. Simply defined these terms are as follows:

Gauss – a unit of magnetic induction such that an induction of one gauss will result in one volt per cm of length in a linear conductor moved perpendicularly across the conductor at a speed of one cm per sec.

Oersted – a unit of magnetic reluctance (resistance offered to the magnetic lines of force) equal to the reluctance of a cm cube of vacuum between parallel surfaces.

Magnetic permeability, expressed in units of MU, is the magnetic permeance of a material compared with air. Air = 1.0 MU. Magnetic permeability is the ratio of magnetic flux density in the material (units of gauss) to the field intensity (units of oersted). Thus units of MU are Gauss/Oersted. Loosely, the magnetic permeability of a material can be viewed as its ability to concentrate or distort a magnetic field.

Measurement of Magnetic Permeability

Military Specification MIL-I-17214A describes a low MU (GO-NOGO) permeability indicator for use in determining the permeability of feebly magnetic materials in all forms used in ship construction. It is capable of differentiating materials of four different permeability levels: 1.2, 1.6, 2.0 and 2.5 (Air = 1.0). Permeability standards may be obtained from the Engineering Experiment Station, Annapolis, Maryland.

Severn Engineering Company manufactures such a high-sensitivity, low-MU permeability indicator permitting bracketing of magnetic permeability between two values. With this all-position instrument, values of less than 2 MU can be readily established.

Estimating Magnetic Permeability (Mu) From Ferrite Level (Fn)

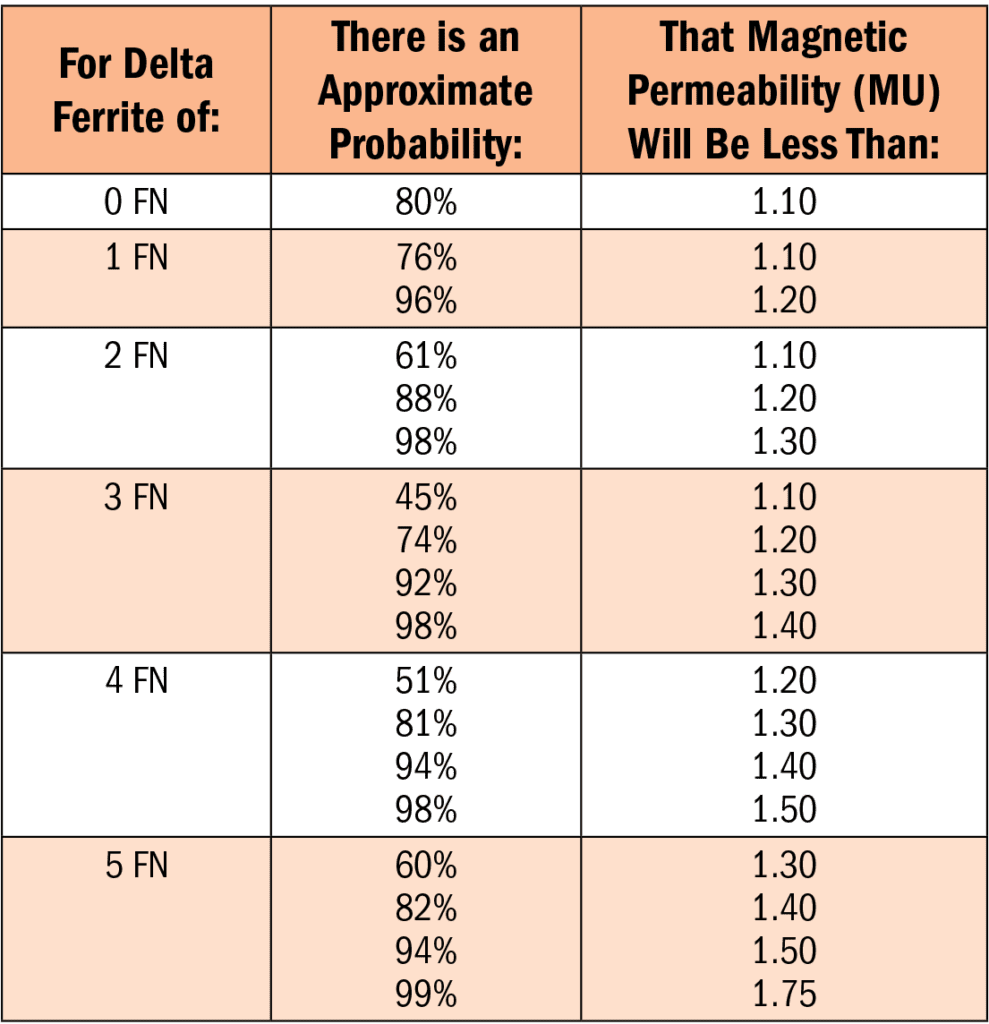

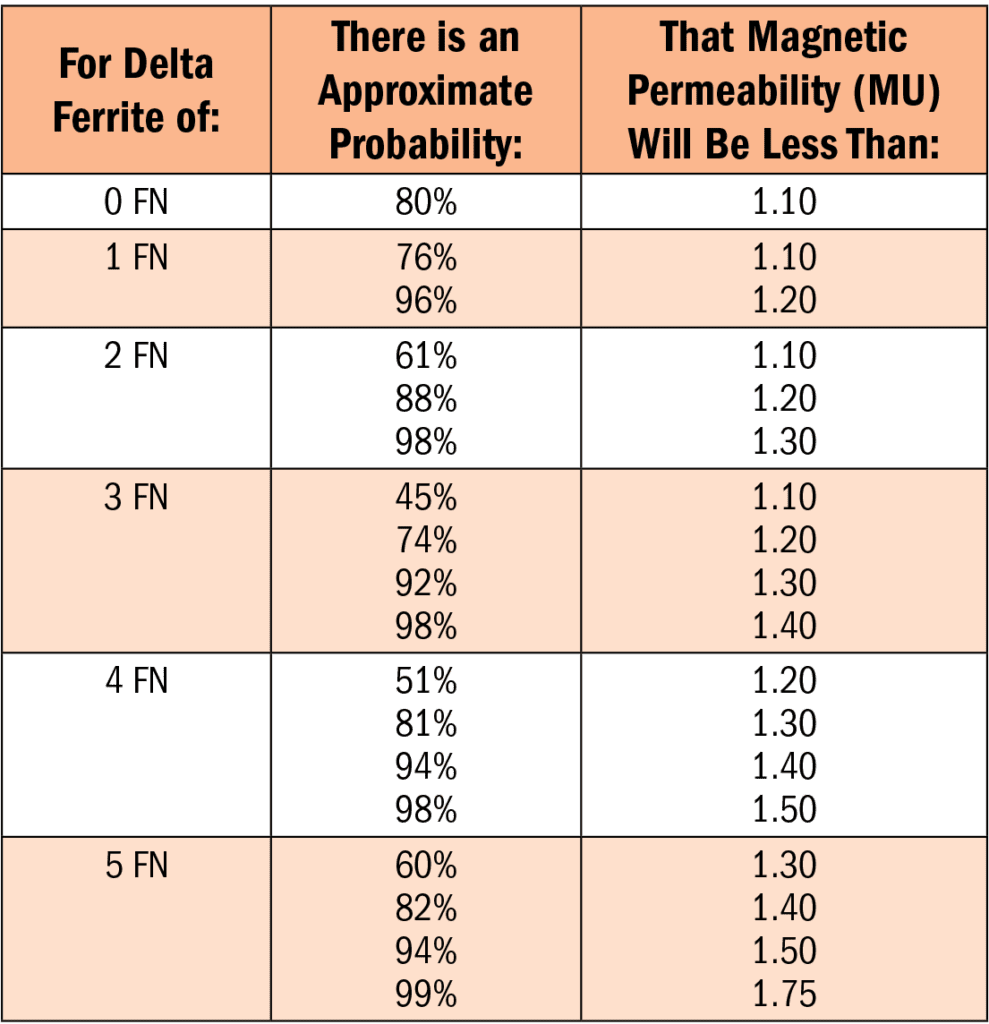

Although a direct relationship between ferrite and permeability is evasive, Figure 27 (adapted from data published by Ebasco Services) provides an educated guess of what magnetic permeability to expect with ferrite levels of 0 to 5 FN.

The data in Figure 27 and Figure 28 indicates that a weld metal Magne-Gage ferrite of 5FN could very well indicate less than 1.75 MU. Therefore, for a magnetic permeability of 2MU maximum, there is reasonable assurance that this requirement can be safely met by specifying a maximum 5 FN (Magne-Gage) and probably met by specifying a maximum of 6 FN.