Manufacturing

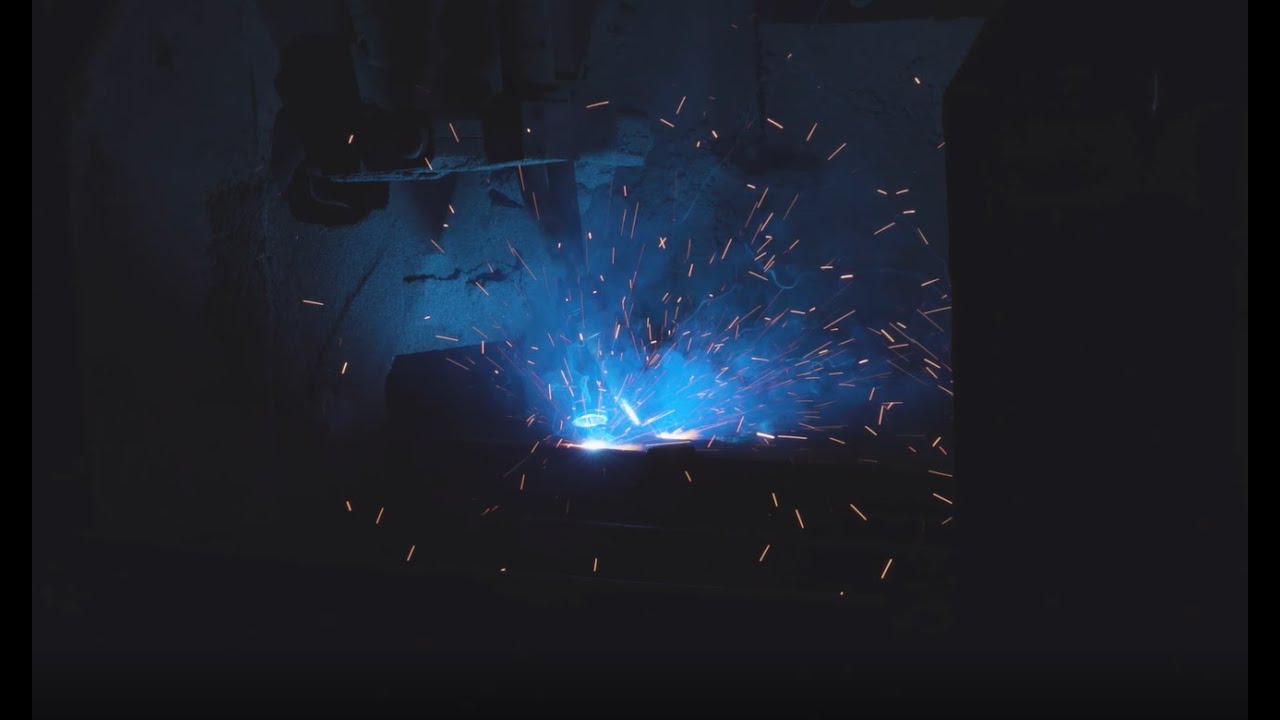

Our World Relies On Manufacturing. Hobart® Filler Metals Are Here To Meet Your Throughput Needs.

Performance. Productivity. Don’t miss out on cost-saving efficiencies. To maximize your operation, you need filler metals that you can count on: Hobart® filler metals.

Rework can bring your operation to a standstill.

High quality output means using the best input materials. Find the perfect Hobart filler metals from our large selection. We’ll make sure that your materials meet your needs and deliver the quality your customer expects, just like we did for Webster Industries.

It’s the tie that binds EFFICIENCY + QUALITY

Webster Industries relies on metal-cored wire for their manufacturing operations. See why they rely on Hobart filler metals.

Products

FabCOR® Edge™ XP

AWS: A5.18: E70C-6M H4; A5.28: E80C-G H4

FabCOR Edge XP is a premium gas-shielded metal cored wired that offers X-CEPTIONAL Performance and Productivity. FabCOR Edge XP delivers the high deposition rates and low spatter you expect from a metal-cored wire, plus excellent weld pool fluidity and balanced arc characteristics from which welders of all skill levels can benefit. FabCOR Edge XP’s best-in-class silicon gathering and weld bead contouring help you do great work—and more of it—in less time.

FabCOR® Edge™

AWS: A5.18: E70C-6M H4

Edge is a metal-cored wire with fewer silicon islands than other metal-cored wires. On clean material, weld bead toe lines are almost completely free of silicon deposits. The weld bead face is virtually free from silicon island deposits. Together with exceptional low spatter rates, Edge will save time and money spent cleaning prior to painting, coating, or plating. The recommended shielding gas is a mixture of argon and carbon dioxide, with a minimum of 75% argon and a maximum of 95% argon. Arc characteristics improve with richer argon gases while spatter and fume levels decrease.

FabCO® Triple 7

AWS: A5.20: E71T-1C/M H8, E71T-9C/M H8 A5.29: E81T1-GC/-GM H8

Intended for single and multiple pass applications in all positions. Designed for carbon and higher strength steels.

FabCO® 811N1

AWS: A5.29: E81T1-Ni1CJ H4/-Ni1MJ H4

All position flux-cored wire used in applications where low temperature notch toughness is required. Can be used on weathering steels when color match is not required.

FabCO® TR-70

AWS: A5.20: E70T-1C H8/-9C H8

This wire has low smoke, spatter and excellent operator appeal For mild and some low alloy steels.

FabCO® 81N1

AWS: A5.29: E80T1-Ni1CJ H8/-Ni1MJ H8

1% nickel deposit. Used in applications where low temperature notch toughness is required. Can be used on weathering types of steel where color match is not required.

SDX S2Si-EM12K

AWS: A5.17: EM12K

SDX S2Si-EM12K is a copper-coated carbon-steel solid wire for submerged arc welding. SDX S2Si-EM12K is a versatile, general purpose product suitable for joining a wide range of non-alloyed steels with a wide variety of flux(es). ** In an effort to best serve the packaging needs and requirements of our customers globally, this product features region-exclusive part numbers. To obtain the complete list of part numbers available in your region, e-mail us at [email protected], contact your regional ITW Welding office, or contact Hobart Brothers customer service (North America) **

SubCOR™ EM13K-S MOD

AWS: A5.17: EC1

SubCOR EM13K-S is a composite electrode for submerged arc welding of carbon steel plates using the recommended fluxes. The electrode chemistry conforms to the solid wire classification EM13K per AWS A5.17.