Stainless Steel Technical Guide

Ferrite, Austenite, Martensite and Solid Solutions

What Are They?

Since the three main classes of stainless steels are named in accordance with their predominant metallurgical phases, e.g. ferritic, austenitic and martensitic, it seems advisable to explain these phases before discussing each stainless steel class in further detail. An elementary knowledge of solid solutions in metals will also lead to a better understanding of stainless steels.

Ferrite And Austenite

Pure iron freezes at 2802°F in a crystal form called ferrite. It has a body-centered cubic (BCC) structure with the basic cell containing one atom at each of eight corners and one atom in the middle. See Figure 3. Upon cooling to 2552°F the ferrite structure transforms into a modification called austenite, the unit cell of which is face-centered cubic (FCC) containing one atom at each of eight corners and one atom on each face (none in the middle). At 1670°F the austenite phase reverts to ferrite, the form stable at room temperature.

Although structurally identical, the ferrite forming at the higher temperature is designated delta ferrite while the ferrite forming at the lower temperature is called alpha ferrite. Austenite is often designated as the gamma phase. Note the gaps between the eight corner atoms are larger in austenite than in ferrite.

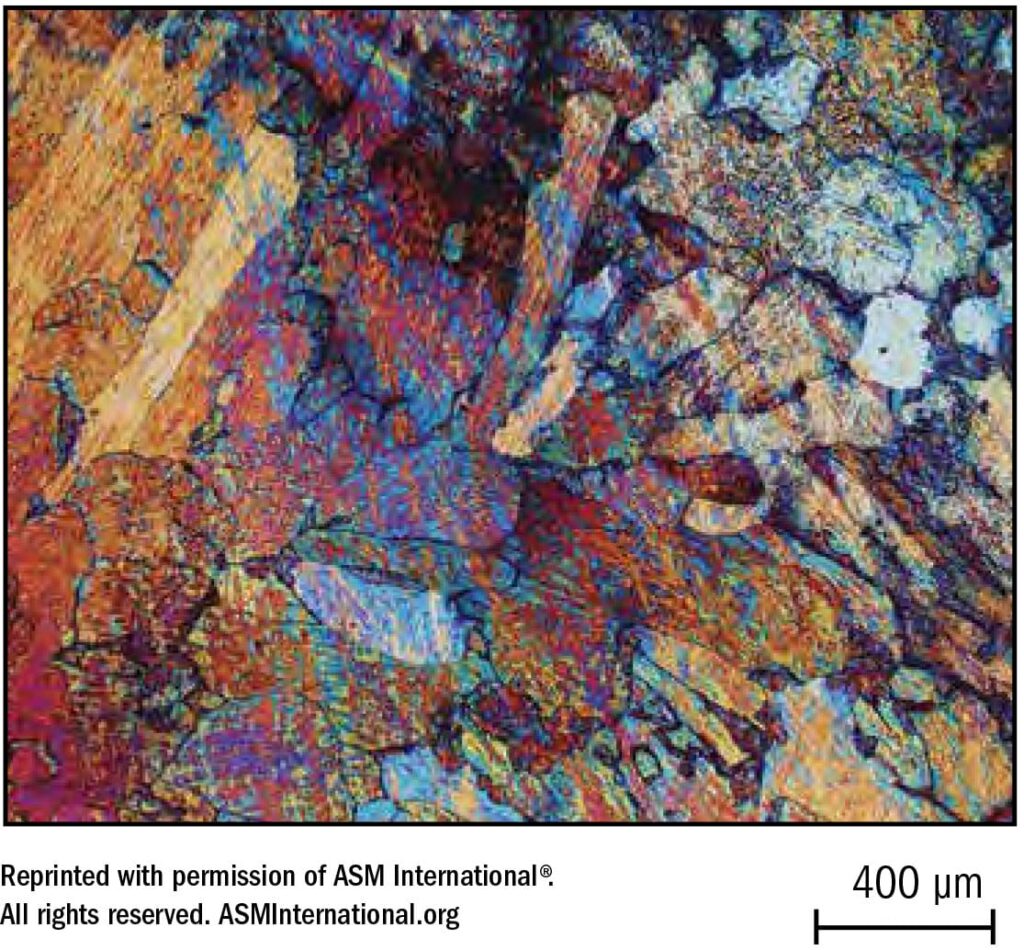

Figure 4 – An As-Welded Weld Deposit on Uns S40900 Type 409 Stainless Steel Magnified 100 Times Showing Large, Columnar Ferrite Grains With Martensite at the Grain Boundaries. The Image Was Produced Using an Optical Light Microscope With Bright-Field (Bf) Illumination and the Etchant Was 3 G Potassium Disulfite, 10 G Sodium Thiosulfate, 2 Ml Hydrochloric Acid and 100 Ml Water.

Figure 4 – An As-Welded Weld Deposit on Uns S40900 Type 409 Stainless Steel Magnified 100 Times Showing Large, Columnar Ferrite Grains With Martensite at the Grain Boundaries. The Image Was Produced Using an Optical Light Microscope With Bright-Field (Bf) Illumination and the Etchant Was 3 G Potassium Disulfite, 10 G Sodium Thiosulfate, 2 Ml Hydrochloric Acid and 100 Ml Water.

Martensite

In commercial steels, the addition of carbon and alloying elements, such as chromium will modify the structure at room temperature in accordance with composition and thermal history. Plain carbon steels, even when cooled rapidly from the austenitizing temperature, develop ferrite and pearlite. Under the microscope at high magnification, pearlite can be identified as alternate platelets of ferrite and iron carbide. The latter is sometimes described as Fe3C or cementite.

The FCC structure of austenite is more compact than the BCC structure of ferrite. During the austenite to ferrite transformation an expansion occurs. Shifting of the atom layers and groups can cause “foreign” atoms to trap and jam, leading to great distortion. When alloy steels containing sufficient carbon and alloy content are cooled rapidly enough from the austenitizing temperature, the distorted structure called martensite is formed — producing high strength and hardness.

Martensite can be described as a distorted arrangement of atoms having a body-centered tetragonal (BCT) unit structure. During fast cooling, the normal transformation from austenite to ferrite that would be expected in a low carbon steel is hindered by the presence of higher carbon and alloying elements and the lack of time to reach a condition of greater equilibrium. Since martensitic structures as-formed are hard and brittle, subsequent heat treatment (tempering) is necessary to reduce their hardness and strength, and increase their ductility to the level required for most industrial applications.

Solid Solutions

We’re all familiar with liquid solutions such as salt in water. If you add salt (the solute) to a cup of hot water (the solvent) the salt dissolves and forms a liquid solution. But if you then put the cup in the refrigerator and examine it several hours later you see a precipitate in the bottom, e.g. some of the salt has come out of the solution. You can say that the solubility of salt in water decreases with decreasing temperature.

The same type of thing occurs in steels. We call them solid solutions. For example, an alloy of iron with about 13% chromium consists of a random mixture of iron (solvent) and chromium (solute) atoms. Iron (Fe) and chromium (Cr) atoms are approximately the same size and about one in seven atoms will be Cr. This distribution of atoms in a crystal (grain) in which the atoms of the second element are evenly distributed in the parent crystal structure is known as a solid solution. Where the Cr atoms are to be found in the same sites as the Fe atoms, the solid solution is known as substitutional.

When you add carbon (C) to the alloy, the C atoms — being smaller than the Fe or Cr atoms — distribute themselves in the gaps (interstices) between the other atoms, assuming the C is under about 0.1%. The carbon then has formed an interstitial solid solution. With C above about 0.1%, the C atoms in excess of the solubility limit may combine with Cr atoms to form chromium carbides.

Certain interstices within the FCC Structure of austenite are considerably more accommodating to C than those of the BCC structure of ferrite. Since the gaps between the atoms are larger in austenite than in ferrite, the solubility of C is greater in austenite but decreases abruptly when, with decreasing temperature, the austenite phase changes to ferrite or martensite.

“Steels” are alloys of iron and carbon with modest quantities of manganese and silicon plus residuals, some of which may be undesirable. Alloying elements such as chromium, nickel, molybdenum, etc. may be added for specific properties. Austenite in stainless steels is considered to be a solid solution of one or more elements in FCC iron.