Aluminum Welding Guide

Filler Metal – MaxalMig® ER4943 and MaxalTig® R4943

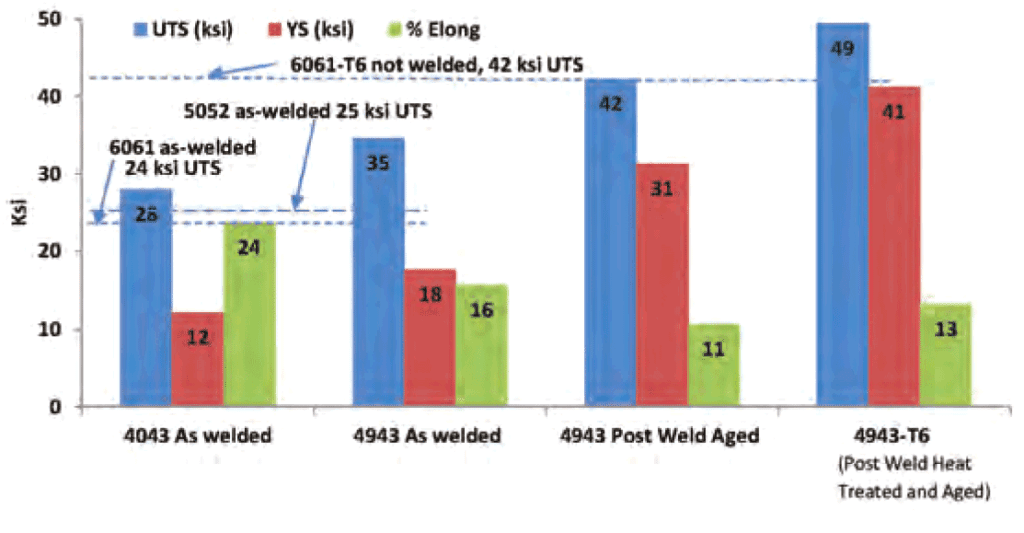

A 25% increase in tensile + shear strength and 50% increase in yield strength

Alloy 4943 filler metal was designed to provide a high strength solution with the ease of welding and other advantages of 4043. Alloy 4043 filler metal is a popular aluminum/silicon filler alloy for general purpose welding applications. Alloy 4943 filler metal was formulated to be welded with the same weld procedure specifications as 4043 and 4643, and does not depend upon dilution from the base metal during welding to increase the strength of the weld deposit, while maintaining the same excellent corrosion characteristics, low melting temperature, low shrinkage rate, higher fluidity, and low hot cracking sensitivity. Welds exhibit low welding smut and low discoloration. 4943 is heat-treatable and exhibits strength levels superior to 4043 and 4643 in post weld age and post weld heat treat and age conditions.

Testing has shown that 4943 will typically provide 25% improved tensile and shear strength as 50% improved yield strength over 4043 in the as-needed condition.

Applications: Current 4043 and 4643 Applications, Welding 1xxx, 3xxx, 4xxx, 5xxx series with up to 2.5% (nominal) Magnesium (Mg) such as 5052 & 6xxx series base metals.

(Refer to the Hobart Aluminum filler metal selection chart for further guidance in selecting filler metals for welding specific base metals.)

- Automotive/motorcycle frames

- Aerospace hardware

- Wheels

- Ship decks

- Furniture

- Post weld age, post weld heat treat & age applications

- Sports products – scooters/bicycles

- General repair and maintenance

- Alloy 356 Castings

- Ladders and frames

Strength Comparison, 4043 vs. 4943

(All weld metal, GMAW, no base metal dilution)

Fillet Weld Strength: The most important benefit of 4943 is to provide consistently higher strength fillet welds. There are far more fillet welds than groove welds used in structural welded components and unlike full penetration groove weld transverse tensile strength, which is controlled by the base metal HAZ, fillet weld shear strength is directly controlled by the strength of the filler metal used during welding. Filler metal shear strength is proportional to filler metal tensile strength. Typical shear strength for 4943 is greater than 15.5 ksi (4043 published value is 11.5 ksi).