GET MORE EFFICIENCY, MORE EASILY

Comprehensive Construction and Fabrication Solutions

In the confab industry, every job is different. Project demands are becoming less predictable, which makes the choice of filler metals vital to running a smooth operation. Performance and consistency are key, which is why using the right filler metal for the job is so important — and why it can have such a big impact on a team’s success.

Hobart® filler metals are highly adaptable for shop or field work and come with the support of our team of experts. Our products are also easy to integrate into existing workflows and have premium weldability, so they’ll deliver high-quality welds across a wide range of applications and conditions.

Be sure to check out these case studies and see how easy it can be to meet project deadlines and increase efficiency.

Hobart® filler metals are highly adaptable for shop or field work and come with the support of our team of experts. Our products are also easy to integrate into existing workflows and have premium weldability, so they’ll deliver high-quality welds across a wide range of applications and conditions.

Be sure to check out these case studies and see how easy it can be to meet project deadlines and increase efficiency.

Why Choose Hobart® Filler Metals?

The short answer is weldability. From the first arc to the last, consistent, high-quality welds set Hobart filler metals apart from the rest. Construction and fabrication experts rely on it —and Hobart delivers, along with guidance on implementation from our specialists whenever you need it.

Highly Adaptable to Many Applications

Whether welding in the shop or out in the field, Hobart filler metals perform across a wide range of applications, equipment and technical requirements.

Enhances Your Team’s Productivity

Higher deposition rates and minimal spatter mean less time cleaning and more time welding. They’re also user-friendly filler metals suitable for a wide range of structural welding applications and processes.

Robust Mechanical and Reduced Defects

Structures in the confab industry carry a lot of weight, both literally and metaphorically. Reliable performace with fewer defects takes a lot of that weight off your shoulders.

Discover Our Range of Filler Metals

FabCO® Triple 7

For single and multiple pass applications in all positions. Designed for carbon and high strength steels.

FabCOR® Elevate™

High productivity filler metal solution for automated and handheld welding. Designed for high deposition rates with reduced cleanup and repair needs.

Fabshield® XLR-8™

Designed for outside use, XLR-8™ is perfect for applications that require all-position capability with low temperature impacts.

Explore Other Confab Solutions

METAL-CORED

FabCOR® Element™ XP

AWS: A5.18: E70C-6M H4

FabCOR Element XP is a new metal-cored wire for both handheld and automated applications. FabCOR Element XP is designed to enhance productivity, improve weldability and boost environmental performance

FabCOR® 86R

AWS: A5.18: E70C-6M H4

Higher deoxidization elements allow this metal cored wire to have more tolerance for mill scale welding applications.

SUB-CORED

SubCOR™ EM13K-S MOD

AS.17:EC1

A composite electrode for submerged arc welding of carbon steel plates using the recommended fluxes. It’s specially formulated to maintain good mechanical properties when welding at high heat inputs.

FLUX-CORED

FabCO® Excel-Arc™ 71

AWS: E71T-1C/M H8, E71T-9C/M H8

All-position wire for both CO2 and mixed gas. For mild and low alloy steel applications.

FabCO® XLNT-6

A5.20: E70T-6

For applications that require a self-shielded high deposition wire with low temperature impact toughness. Designed for use outside

FabCO® RXR

A5.20: E70T-1C/-9C

RXR is an E70T-1 wire that has a higher level of de-oxidizing elements to handle mill scale, rust and other contaminants.

STICK

Hobart® 418

AWS: E7018 H4R, E7018-1 H4R

Good general purpose low hydrogen electrode. Easy to use in all welding positions, with excellent arc stability, low spatter levels and easy slag removal.

Hobart® 610

AWS: E6010

Premium cellulose stick electrode designed for the pipe welding and construction industries. It has low spatter and easy slag removal, with excellent operator control.

Hobart® 335A

AWS: E6011

Cellulose electrode with penetrating characteristics designed to handle coated steels. Used primarily with AC power sources but can be used with DC currents.

A Custom Filler Metal Solution for the San Francisco-Oakland Bay Bridge

Every day, 250,000 vehicles cross the San Francisco-Oakland Bay Bridge. So when it needed reconstruction, the engineers at Portland State University turned to Hobart Filler Metals. Its critical support structures needed a special, low-hydrogen filler metal. See how Hobart worked directly with the project’s engineers to custom design a solution for this extremely challenging job.

Hobart emerged as the most consistently best wire with a low hydrogen due to Hobart’s business core technology.

Dr. Bill Wood

Mechanical Materials Engineer – Portland State University

Mechanical Materials Engineer – Portland State University

Joint spaces, the scale of the entire operation the work environment we were in, it was all quite challenging.

Bob Turpin

Senior Research Engineer – Portland State University

Senior Research Engineer – Portland State University

Talk with a Confab Expert

Resources for the Confab Industry

Metal-Cored Wire Maximizes Success

Moving From Stick Electrodes To Self-Shielded Flux-Cored Welding Wire: Part One

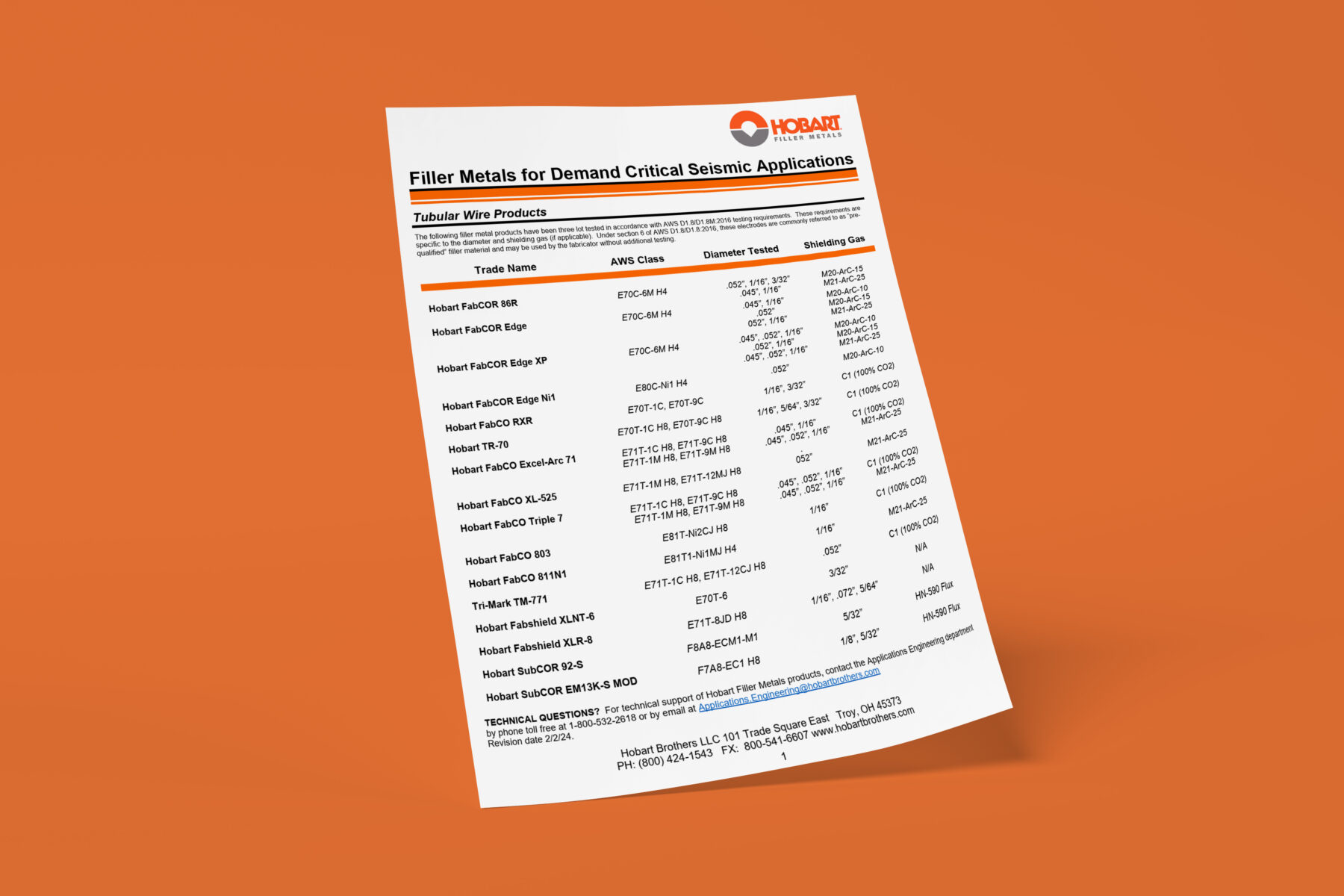

Filler Metals for Demand Critical Seismic Applications

How Alamo Saved Big by Switching from a Leading Competitor’s Metal-Cored Wire to Hobart

Frequently Asked Questions

Do your products meet Buy America?

Do union training facilities qualify for an education discount?

Why do some products require DCEN and some require DCEP?

Do you offer products that meet D1.8 Seismic Requirements?

What packaging options are available?

What products do you have for the confab space?

Are actual mechanical and chemistry data available?