Welding Pain Points Eliminated with Simple Consumable Swaps

Leading tractor drag manufacturer needs operational optimization

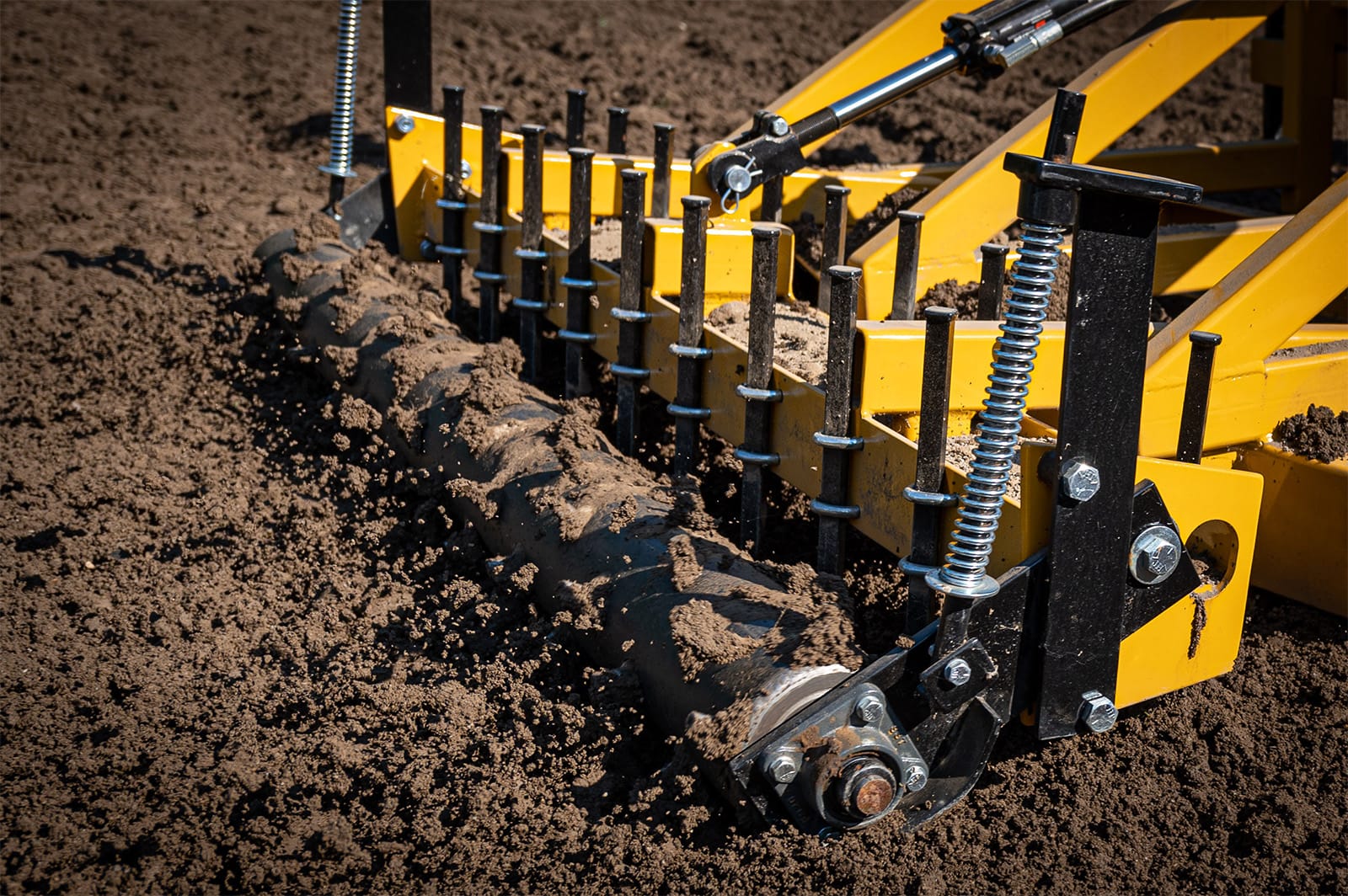

From barrel racers and baseball players to landscapers and farmers, Reveal 4-N-1 has been an integral part of those industries behind the scenes. The company is the leading manufacturer of multipurpose ground prep tractor drags — an essential piece of equipment in agricultural use, ball field maintenance and in the arenas for various riding needs. Reveal 4-N-1 is the only company endorsed by the National Barrel Horse Association (NBHA) and American Novice Horse Association (ANHA) — a testament to its quality and reputation. Sold throughout the United States and with a growing global presence, the company is focused on producing its equipment at a pace that can keep up with demand. Reveal 4-N-1 knew it was time to assess its operations and optimize where possible — it just didn’t realize it was going to happen during a seemingly routine equipment pickup.

Reviewing the welding process and identifying problem areas

A personal user of Reveal 4-N-1, Jake, a member of the Hobart Filler Metals PIT group (process improvement team), was onsite at the company’s Ohio facility ready to pick up his new tractor drag. As a PIT team member, he has an eye for uncovering potential manufacturing obstacles and helping professionals enhance their skill set. His admiration of the product and interest in fabrication caused him to start a conversation with the owner, which eventually led to him asking if he could see their shop and manufacturing process.

After observing the operations and asking process-related questions, it came to light, that the welding team was consistently experiencing several issues, including:

- Excessive weld spatter, requiring grinding prior to painting.

- Distortion of welded components which made part changeover difficult.

- Burning through areas with gaps.

Jake then evaluated their equipment and consumables. He noted that the wire diameter and composition was not ideal for the material thickness. In addition, the ER70S6 solid wire being used was of lower-tier quality. Those two factors were the primary contributors to the technical issues experienced during the welding process — and resulted in a fair amount of non-value labor being expelled in post weld clean up. Armed with this information, an opportunity to help improve their processes and productivity was uncovered.

Quality consumables streamline production and improve output.

Once Jake returned to work, he sent Reveal 4-N-1 Hobart 86R filler metal and AccuLock™ tips and nozzles to help improve weld quality, increase productivity and extend the life of their tips and nozzles. He told them to call once they received the products so he could give them the parameters to run for optimum weld quality and troubleshoot any immediate issues.

Within just one week, Reveal 4-N-1 called Jake back with a very positive message: He had changed their entire operation — for the better! The primary welder was impressed with the products because they didn’t spit and pop, making the overall job (and his day) more enjoyable. Key results included:

- Increased part throughput.

- Longer lifespan from the tips and nozzles.

- Less part distortion.

- Near-elimination of weld spatter, scraping and grinding.

- Improved handling of gaps with near elimination of punching through.

- Parts released easily from the weld tooling.

- “Using the 86R Metal Core wire has been a huge improvement for our shop. I have seen a 25% reduction in labor costs since switching to the new wire.” – Ken Reveal, owner of Reveal 4-N-1

Using higher-quality wire and consumables, Hobart Filler Metals was able to eliminate the pain points Reveal 4-N-1 was experiencing and optimize productivity and operating costs. The improvements in the finished weld allowed labor to be reallocated to other parts of the operation, further helping to meet manufacturing demand.

Up until that day, Reveal 4-N-1 was more focused on meeting their production needs, than digging into current technology and support that could improve their processes. They had never had a vendor offer the level of knowledge and assistance that Hobart Filler Metals provided. Reveal 4-N-1 feels confident that their product is now even better with the simple changes to their operations — and just as important, they know they have the support of Hobart behind them whenever they need it.