Understanding Filler Metal LAST Testing for Demand Critical Welds

The 1994 Northridge earthquake changed the course of welding codes for structural steel applications. The severe damage sustained by welded steel moment connections during the event prompted the FEMA/SAC program to begin extensive research to determine new regulations to protect against future such catastrophes. The subsequent research conducted by the program, according to the American Welding Society (AWS) D1.8—Structural Welding Code—Seismic Supplement, determined that “additional controls on design, detailing, materials, workmanship, testing, and inspection [were] necessary.”

filler metals’ mechanical properties to ensure they

have been tested at the correct LAST for their

applications before beginning the welding operation.

The AWS D1.8/D1.8M, Structural Welding Code—Seismic Supplement, along with the requirements of AWS D1.1/D1.1M,Structural Welding Code – Steel, replaced the now defunct FEMA 353 recommendations in 2005, setting forth the welding requirements that engineers and contractors must adhere to for seismic Demand Critical welds in welded steel moment connections.

The code requires filler metals for these welds to have a Charpy Vee Notch (CVN) impact minimum value of 20 ft-lbs at 0 degrees F under standard requirements of the appropriate AWS A5.XX specification. Filler metals that are classified with a lower CVN testing temperature are also acceptable, for example, those with a classification test temperature of -20, -40 degrees Fahrenheit.

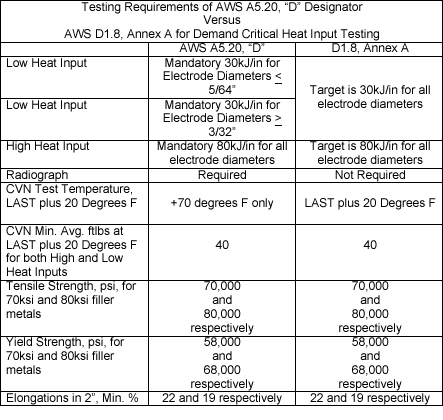

In addition, the code provides details for additional low and high heat input testing required for these connections to establish a heat input working envelope. For flux-cored filler metals, one option is the optional “D” designator. This designator has been set forth per AWS A5.20/A5.20M:2005 – Carbon Steel Electrodes for Flux-Cored Arc Welding and also AWS D1.8 Annex A for flux-cored and other filler metals, such as metal-cored wires. The “D” designator applies only to flux-cored (FCAW) carbon steel electrodes, but AWS D1.8 allows the testing requirements also to extend to low alloy FCAW electrodes in AWS A5.29/A5.29M.

When electrodes meet the testing requirements of the optional ”D” designator for flux-cored wires, or AWS D1.8 Annex A for flux-cored or other filler metals, these products are considered to have adequate mechanical properties at high and low heat inputs for Demand Critical weld applications. For both requirements, the filler metal must be able to provide a weld deposit with a CVN toughness of 40 ft-lbs. at +70 degrees F, for a Lowest Anticipated Service Temperature (LAST) of +50 degrees F, meaning it is the lowest temperature the completed weld will encounter in service.

The CVN test temperature for “D” designator filler metals is determined by the LAST plus 20 degrees, hence, +50 degrees F plus 20 degrees equals a CVN test temperature of +70 degrees F. When LAST temperature is below +50 degrees F, however, AWS D1.8 Annex A regulations apply instead. For that reason, engineers and contractors need to remember that just because filler metals have a “D” designator, they are not necessarily suitable for all seismic applications. Instead, these filler metals will need to be tested to the correct LAST for Demand Critical welded connections for the structure environment before fabrication or erection begins.

Some the differences in the “D” designator and Annex A are as follows:

Understanding Filler Metals for LAST

Providing the appropriate toughness of 40 ft-lbs is typically emphasized in LAST testing. However, 70 ksi filler metals must also provide a minimum tensile strength of 70 ksi, a minimum yield strength of 58 ksi, and a minimum elongation 22% typically for welding A36, A572 grade 50 and A992 steel. The 80 ksi filler metals typically used for A913 grade 65 steel need to be capable of providing 80 ksi minimum tensile strength with a minimum yield strength of 68 ksi and a minimum elongation of 19% at both the low and high heat input test results regardless of LAST.

When LAST temperature for an application falls below +50 degrees F, the requirements are no longer valid for the FCAW optional designator “D” or filler metals tested to AWS D1.8 Annex A at this temperature. Filler metal testing is then conducted using AWS D1.8 Annex A for the specified LAST.

Contractors or engineers can work with their filler metal manufacturer or a third party to perform this testing. In some cases, additional lot testing for the filler metals will be required at the lower LAST.

The testing agency or filler metal manufacturer will test the filler metal at the specified LAST for the application, plus 20 degrees. For example, if an application is expected to have +20 degree F LAST, the CVN test temperature will be +40 degrees F (+20 degrees F plus 20 degrees). In accordance with this testing, the filler metal must be capable of maintaining its mechanical requirements at that temperature.

A CVN average value of 40 ft-lbs is still required of both the low and high heat input at this lower test temperature. Such testing is critical to ensure that the final weldment will have the appropriate strength and toughness at a given service temperature in a seismic event.

Final Thoughts

Contractors or engineers should never automatically assume their current filler metals meet the LAST requirements. Instead, they should assess the filler metals’ mechanical properties to ensure they have been tested at the correct LAST for their applications before beginning the welding operation. Doing so protects the welding operation from costly delays and rework, and also ensures the best quality of the weldment.