Tensile Strength Is Critical for Medical Equipment Manufacturer

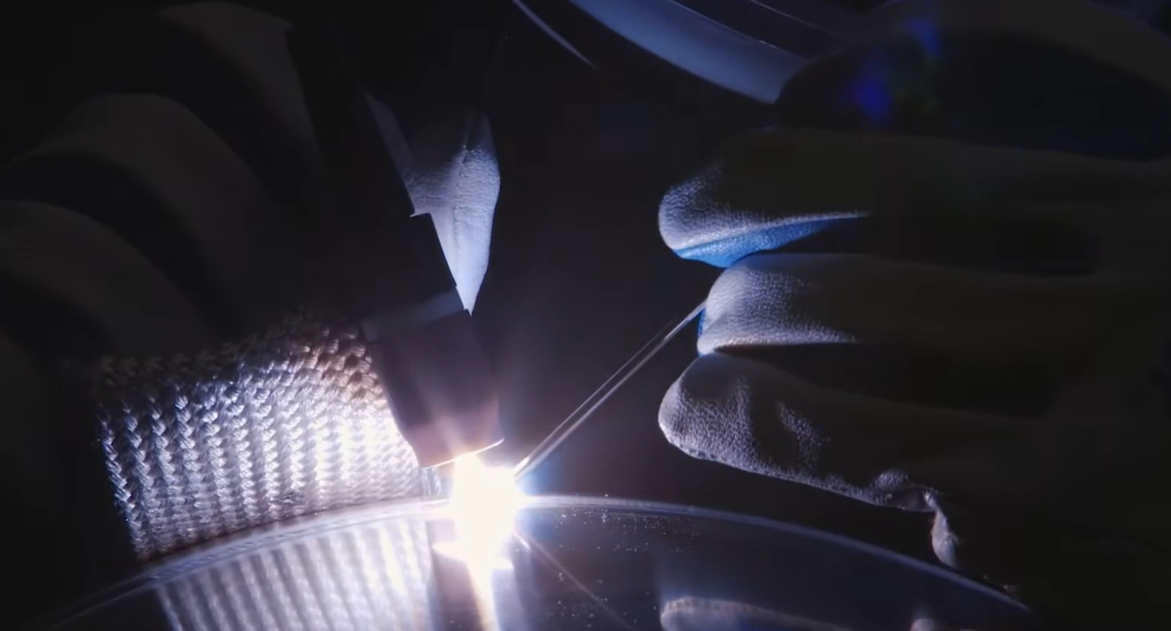

Fort Defiance Industries knew gaining a Department of Defense contract meant weld strength would be critical – so they turned to Hobart 4943 TIG rods. When bidding for the contract to produce automated steam field sterilizers for the Department of Defense, Fort Defiance Industries had to quickly develop a prototype that was reliable, durable and stood up to hydrostatic testing. The right filler metal was essential to ensure the necessary weld quality and strength. Hobart MaxalTig® 4943 aluminum filler metal delivered a 2,000 psi increase in tensile strength, ensuring welds would stand up to the harshest conditions in the world. Using the 4943 filler metal, FDI has manufactured about 180 steam sterilizers and will produce hundreds more to satisfy the government contract it secured.

Video Transcript

The greatest benefit for us has been the increased strength that we knew we would get with the Hobart 4943. The 4943 gave us a 2,000 psi bump in tensile strength over the 4043 that we had previously chosen. So that’s really a big upgrade and it’s something that we want to use because of the strength. We want all the strength we can get in a pressure vessel. It’s a big deal from a safety standpoint so that increased strength was the primary reason that we went to the 4943.