Solutions to Improve Aluminum Weld Quality and Strength

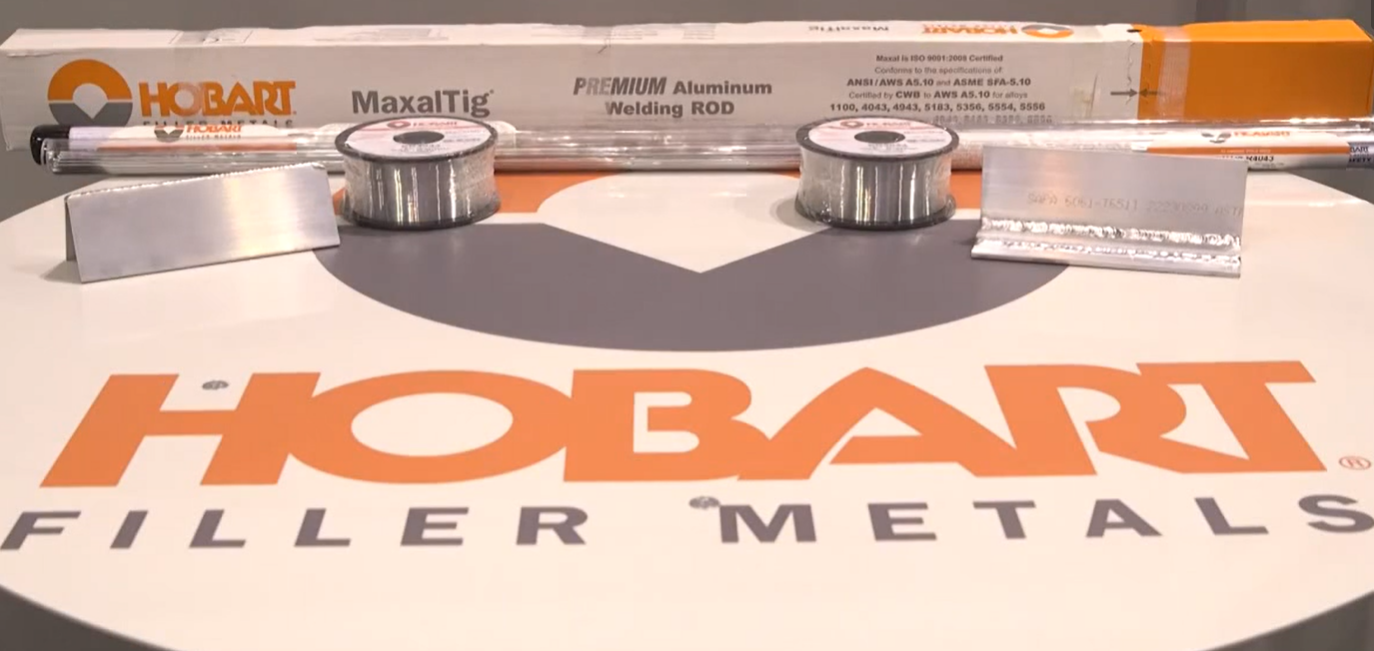

Miller and Hobart offer equipment and filler metal solutions to improve aluminum weld quality, and are showcasing these products at FABTECH 2015. Learn from Blaine Guy, welding engineer, about the benefits of combining Miller machines with Hobart wire and TIG cut lengths. Visit booth 14032 for more details.