Railcar Manufacturer Saves Time and Money, Simplifies Welding Operator Training with Change to Hobart Wire

Extensive employee training is a way of life at FreightCar America, a company that’s been manufacturing railcars for over 100 years.

The process for new employees includes hours of hands-on training and the pursuit of a variety of American Welding Society (AWS) certifications, illustrating both the pride the company takes in the quality products they manufacture and the value they place in their workforce.

production facility in the Shoals region of Alabama. After launching

the location with two production lines for hopper and aggregate

railcars, FreightCar America underwent an evaluation of its welding

process in an effort to fix frequent wire feeding issues, such as birdnesting.

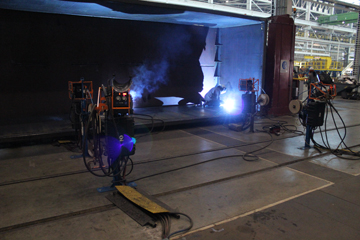

When FreightCar America moved into its newest location, a state-of-the-art railcar production facility in the Shoals region of Alabama, it was part of a plan to expand the company’s railcar offerings and products beyond the traditional coal car market. The facility is just shy of one mile from end-to-end, and when fully operational offers the capacity to build over 5,000 railcars per year.

“I think customers see the smooth transition of the way this plant is set up, how much it can actually put out,” says Todd Wood, a weld technician for FreightCar America. “They want quality and they want to meet deadlines. They want the cars on time.”

Launching production at the Alabama location required hiring and training enough welding operators for FreightCar America to get the first railcar lines up and running, with plans for growth in 2014. The company needed more than 130 welding operators to work the day shift for the first two production lines the company set up — a hopper car line and an aggregate car line.

In the first few months of production, however, FreightCar weld technicians who reviewed daily quality reports noticed issues with frequent birdnesting, which occurs when welding wire gets tangled in the drive rolls, and backlash of the metal-cored wire used for much of the welding. Sometimes a broken wire inside of the contact tip would require tip replacement. The downtime spent fixing these issues and the extra cost of the more frequent replacement of consumables were problems FreightCar America wanted to address — not just for quality and productivity reasons, but also to simplify welding for its newly trained employees.

After an evaluation of the welding process at the facility, FreightCar America made the switch to a metal-cored filler metal from Hobart® — the Hobart FabCOR® Edge™MC — for much of the welding on the main floor. The change resulted in improved productivity and quality, reduced downtime spent dealing with wire feeding issues and simplified training of new welding operators.

“If you’re not having to deal with fixing your welder all of the time, you can just weld and do your job,” says Athena Hinkle, a FreightCar America weld technician. “The Hobart Edge MC wire has really changed the way our workday goes. Anytime you’re having to stop, you’re taking away from when you could be working, and we’re not having to do that as much now.”

Problems with the previous wire

The frequent wire birdnesting and breakage that resulted in backlash of the wire inside the drive roll took a toll on the tight production schedule at the FreightCar America facility. On some days, weld technicians had to address tip problems or birdnesting issues multiple times.

Sometimes the problems would happen back-to-back on the same machine, leading to frustration for the welding operators, particularly those who were newly trained. It was especially troublesome when it happened after the welding operator had maneuvered into a tight position to make a weld.

Edge MC — for much of the welding on the main floor at FreightCar

America resulted in improved productivity and quality thanks to

reduced downtime spent dealing with wire feeding issues. The

company reduced more than seven hours of downtime daily for

a section with eight welding operators.

“They’d go to strike the arc and it pops and burns back and then they’d have to stop, pull the wire out and redo it,” Wood says. “When it’s a recurring issue, then it gets the guy that’s running that machine aggravated.”

Operators also noticed issues with tight casting of the previous wire and a tendency for it to twist as the spools rolled.

Making the switch

Plant management decided an evaluation of the welding process was necessary to see what improvements could be made. In conjunction with their Hobart representative and their welding distributor, Darryl Faulkner, Airgas South in Muscle Shoals, Alabama, they went through the Hobart Toolbox process. This process evaluates cycle times, quality, costs, downtime and other factors for manufacturing and production operations, looking at the existing processes and identifying opportunities for improvement.

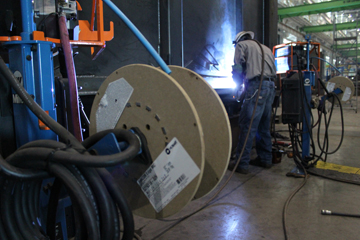

Wire feeding was flagged as one of the biggest problems, so FreightCar America began testing a .052 diameter FabCOR Edge MC wire in the plant’s weld school training facility for new hires as a first step.

“We had a new person in training, she had basically come straight off the street and had never welded in her life,” Wood says. “She started out with a competitor’s wire and it showed that she had never welded. So all we did was swap out the wire, she ran a bead [with the FabCOR Edge MC], and it was probably one of the prettiest ones I’ve seen. No more than changing the wire, and it was that much more forgiving.”

That test convinced FreightCar America to use the FabCOR Edge MC wire for most of the welding on the plant floor. The hopper cars require welding mostly 3/16 to 1/4 inch steel, while the aggregate railcar welds range from 3/16 to 3/8 inch steel.

The Hobart Toolbox also showed what the financial impact of the switch would be, through a return on investment analysis that took into account how much the company could save in repair and cleanup time and labor productivity costs.

wire make it more forgiving for stick-out changes, hand

fluctuations and other factors, which is especially important

for a facility training many new welding operators.

“We were actually able to eliminate more than seven hours of wasted time in a day, and that’s in one section of eight people,” Wood says. “You have to think about, each person was losing about 15 minutes out of every hour. So when you spread it across the whole line, it was almost an entire person just by changing the wire out. That was a real savings we saw immediately.”

The wider range of welding parameters allowed by the new wire also make it more forgiving for stick-out changes, hand fluctuations and other factors, which is especially important for a facility training many new welding operators.

“It allows for a learning curve, and then it gives you great results. It lets you run a lot more consistent bead,” Wood says. “If you can run a smaller wire and get the same deposition rate or better and make the quality of the weld look a lot better, that’s what I am going to try to put on the line.”

When a wire allows for a wider range of welding parameters, welding operators can slightly adjust their settings according to preference, since everyone has nuances to his or her technique.

“It’s not a locked in amperage we have to follow by,” Hinkle says. “It’s a lot better for the new employees. They’re not having to wait and stop and fix stuff all of the time.”

Simplified training

New welding operators at FreightCar America go through 40 hours of weld school training and get AWS certifications in numerous areas before they start work on the railcar lines.

hours of weld school training through a partnership with

Navistar and get AWS certifications in numerous areas before

they start work on the railcar lines.

The FabCOR Edge MC wire makes it possible to start new welding operators out at lower amperages and slower speeds — without creating a lot of spatter, which typically happens at lower amperages and slower speeds — so they can get the technique down. As they get used to the process, they can run hotter and faster to increase productivity.

“Before, training would take longer because you’re having to deal with a lot of discrepancy issues and you’re having to pause so much to fix other stuff,” Wood says. “Now, they’re not having to deal with spatter and stuff as much, so they’re not having to go back and go over their welds.”

A more forgiving wire is easier for welding operators to handle and results in fewer weld defects at the FreightCar America facility.

“It makes my job a whole lot easier,” Wood says.

Quality and productivity benefits

The higher deposition rates of the wire combined with the reduced need to stop the welding process to fix birdnesting or replace contact tips resulted in productivity and quality gains for FreightCar America. The more forgiving characteristics of the wire and smoother spray transfer also play a role in improved bead quality and appearance.

FreightCar America also sees time and money savings from the reduced post-weld cleanup, since the wire produces less spatter than what they were previously using.

“If I can keep a continuous weld, I don’t have a lot of silica and stuff like that on it and hardly any spatter. I know with this wire what amps I can run on it to make it look good,” Hinkle says.

In addition to the productivity gains, the company saves money by greatly reducing the amount of wasted wire and contact tips.

A difference maker

While some companies may be reluctant to change the type of wire they’re using in welding applications, FreightCar America went through the evaluation and realized the switch would pay off in greater productivity and quality, and improved operator training.

It’s quality that FreightCar America customers notice, and the FabCOR Edge MC is a forgiving wire that FreightCar America welding operators are happy to use.

“Once you get the demo, it sells itself,” Wood says. “I’ve used different types of wires and welded with a lot of different wires, and the Hobart is the best I’ve used yet.”