How to Choose Packaging for Welding Wire

When looking at ways to improve productivity, quality and cost savings in the welding process, equipment, filler metals and labor are all important factors. The type and weight of welding wire packaging can also make a difference. The goal when making the selection is to balance out the time and cost for changeover of the package with the equipment to be used and the rate at which the product will be consumed.

Too small of filler metal packaging increases changeover rates, while too large of packaging can cause welding wire to sit on a shop floor for an extended period of time. That can lead to potential moisture pickup on the wire and poor welding performance — not to mention it may void the manufacturer’s warranty for the product if storage time is excessive or storage is improper.

Available packaging options

There are three main packages for welding wire: spools, coils and drums. The available equipment and volume of production determines the best size or weight for the job.

Welding wire spools include a hub on circular fiberboard, plastic or steel flanges that mounts on the spindle assembly of a bench feeder or suitcase feeder. Spools are typically available in weights ranging from 33 to 55 pounds for industrial applications. Smaller diameters and weights are also available for specialty or commercial applications.

Welding wire coils are generally available in weights between 50 and 60 pounds and consist of wire wound around a cardboard insert. Coils do not contain the hub needed for mounting on a wire feeder and, therefore, require an adapter. The adapter adds an expense to the operation but is designed used many times. Also, the upfront cost for coils tends to be less than spools.

Welding wire drums for carbon and low-alloy steel typically weigh between 500 and 1,000 pounds and are designed for high-volume welding operations. Some filler metal manufacturers offer 100- and 300-pound drums for aluminum welding wire.

Reasons to change

There are several reasons to consider changing the type and weight of welding wire packaging. The most common is cost.

Bulk welding wire in heavier drums requires less changeover — and less changeover reduces downtime, allowing more time for welding. Since labor is the largest contributing cost in the welding operation, minimizing the amount of time operators change over wire is critical.

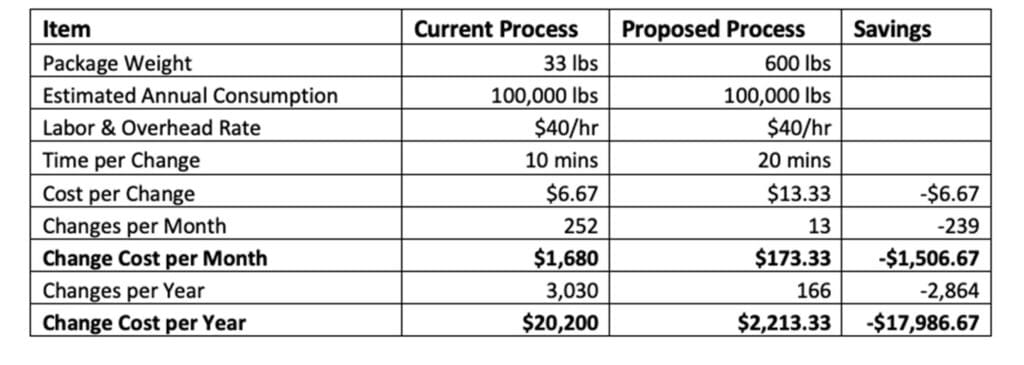

Consider a company converting from a 33-pound spool to a 600-pound drum. Based on the chart below, this switch minimizes changeovers from 252 per month to 13, yielding an annual labor savings of nearly $18,000.

As a side note, some bulk package options may have a slightly higher cost per pound of wire compared to coils; however, minimizing changeover and the associated labor costs can more than make up the difference.

In addition to cost, the need to simplify recycling and waste disposal may prompt a change to a new type of packaging. For example, if a company wants to reduce waste, it may consider converting from fiberboard spools to welding wire on steel reels that can be placed in the steel scrap bin for recycling.

Some filler metal manufacturers also offer cardboard welding wire drums without metal chime rings at the top that are 100% recyclable. Again, these may be appealing for companies looking to reduce waste and/or streamline their recycling programs.

fiberboard, plastic or steel flanges that mounts

on the spindle assembly of a bench feeder or

suitcase feeder.

What to consider

When converting to a different welding wire package type or weight, there are several factors to consider.

1. Environmental exposure: Certain welding wires readily absorb moisture outside of their original packaging. Gas-shielded flux-cored (FCAW) wires, for instance, are more prone to this issue than metal-cored wires. Drum packaging and accessories can offer protection, as the wire remains contained within them during storage and use. This helps reduce exposure to dust or dirt from the environment that can lead to feeding issues. Spool covers offer a similar level of protection. Also, certain welding codes dictate the amount of time a wire can be out of original packaging and exposed to the atmosphere — the chosen package will need to be large enough for the job (to minimize changeover), but small enough to be used in the allotted time to avoid scrapping the welding wire.

2. Proper setup: When converting to a drum, welding operators need to receive the proper training for setup to ensure smooth wire feeding and good welding performance. Consult the filler metal manufacturer’s guidelines.

3. Material handling: Per OSHA, “lifting loads heavier than about 50 pounds will increase the risk of injury.”[1]For spools or coils weighing more than 50 pounds, welding personnel should consider team-lifting the wire when adding it to the feeder. Welding wire drums require a drum lifter or forklift to move the package into the desired position in the weld cell. The specific lifting equipment depends on the drum. Some have chime rings that a drum lift latches onto, some have lifting handles, while other drums slots for forklift tines.

weights between 50 and 60 pounds and consist

of wire wound around a cardboard insert.

4. Required accessories: As mentioned previously, a welding wire coil requires adapters that allow it to be mounted on a wire feeder. When converting to a drum, companies need to invest in conduits and fittings. The conduit bridges the wire from the drum to the feeder to help ensure smooth wire delivery, while the fittings create a firm connection between the drum and the conduit. These accessories are used in conjunction with drum hoods (also known as cones or hats), which also help smooth wire feeding and minimize the opportunity for dirt or debris to enter the drum. Cones, hoods and hats must be the same diameter as the drum with which they will be used. Lastly, when welding with larger wire diameters — typically 5/64 inch and above — a mechanical turn table that rotates the drum is necessary to gain proper wire feeding.

Additional thoughts

When selecting a welding wire package, consider the volume of production, the application, space availability and whether portability is necessary — in which case a spool or coil would be more appropriate compared to a drum. In terms of cost assessment, consult a filler metal manufacturer to explore potential savings associated with new type or weight of package.

[1] https://www.osha.gov/SLTC/etools/electricalcontractors/materials/heavy.html