Galvanized Steel Welding: Is It Really Worth the Trouble?

In automotive applications, galvanized steel has become an increasingly viable option for manufacturers to build lighter-weight vehicles capable of offering greater gas mileage — without sacrificing quality or safety. Due to the protective layer of zinc oxide on its surface, the material offers excellent corrosion resistance, as well as high strengths, even at thinner gauges.

Many automotive manufacturers utilize galvanized steel in the 1.6 to 4 millimeter range, for components such as frames, engine cradles and suspension links, and use even thinner measurements for other areas of the vehicle. In fact, it’s not uncommon to find components like auto body skins measuring as thin as 0.7 millimeters.

Galvanized steel’s most positive attributes, however, are also the very things that make the material so challenging to weld. Its thinness increases the opportunity for burn-through, while the zinc oxide coating contributes to defects when welded incorrectly. In both cases, should these issues arise, manufacturers risk sacrificing quality and productivity, which can adversely affect their competitive edge and their bottom line.

Recent advancements in filler metal technology, as well as welding equipment, are now providing automotive manufacturers with new ways to address these challenges and to improve their overall galvanized steel welding operations.

The welding challenges

Most automotive manufacturers use one of three types of galvanized steel: hot-dipped, galvannealed or electro-galvanized. Of these, the hot-dipped galvanized steels tend to be the most challenging to weld, but also the most prevalent in the industry due to their lower cost. As a result of the specific galvanizing process, this material tends to have an uneven surface thickness that makes the completion of consistent welds particularly challenging. To obtain its zinc oxide finish, the material passes through molten zinc at high temperatures (over 427 degrees Celsius or 800 degrees Fahrenheit), after which the zinc undergoes a series of chemical reactions (e.g., with oxygen and carbon dioxide). The result is the tough zinc oxide surface, which provides the protective barrier and acts as a sacrificial anode for corrosion resistance.

Most automotive manufacturers use the Gas Metal Arc Welding (GMAW or MIG/MAG) process, either Pulsed or Constant Voltage (CV), with a solid wire for welding hot-dipped galvanized steels. Both processes, however, have proven difficult when it comes to gaining consistency in weld quality at similar travel speeds as those used to weld mild steel.

Spatter is one troublesome issue that arises and is typically the result of the shorter arc lengths associated with CV modes of welding.

Porosity is by far a greater problem and the travel speeds used during the welding process directly impact this weld defect. The faster the travel speed on hot-dipped galvanized steel, the faster the weld pool tends to freeze. That is especially troublesome since zinc vaporizes at a much lower temperature than steel. The temperature differentiation can lead to gas pockets becoming entrapped because the weld solidifies before the zinc gas can escape.

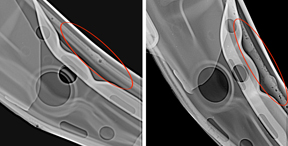

In this situation, the welds may have a good outward appearance, but have significant subsurface porosity. In some cases the porosity appears as small pockets, but it can often span the entire length of a weld joint in the form of a defect referred to as piping or worm tracking. In other cases, there is the potential for porosity to create a linear path that can lead to an “unzippering” effect during cyclic loading.

steel applications (as shown in these X-ray images

— a metal-cored wire weld is on the left); however,

being able to minimize this porosity while also

repeatedly maximizing travel speed is key to

supporting high quality and productivity in automotive

manufacturing.

At certain levels, porosity or worm tracking is acceptable. The range varies according to each manufacturer, but is typically based on American Welding Society (AWS) specifications. As a rule, individual instances of porosity need to be separated by at least their own diameter and the total length of porosity (sum of diameters) should not exceed 6.4 mm in any 25 mm (or 1/4 inch in any 1 inch) of weld. The maximum diameter of any instance of porosity should also not exceed 1.6 mm (1/16 inch). Internal porosity is generally limited to less than 25 percent of the area being inspected.If the amount of the defect is detected in the subsurface of the weld and exceeds the allowable limits for a given component, it leads to rework or scrapping of those parts.

To compensate for these issues, automotive manufacturers often lower travel speeds. While this solution may address quality in a positive way, it can also affect productivity negatively. Slower travel speeds equal fewer welds and lower net throughput. It also can affect capital outlay and real estate requirements, and shift production bottlenecks.

New filler metal and welding equipment solutions

There are two ways in which automotive manufacturers can more readily address the challenges of welding hot-dipped galvanized steel.

First, they can pair their current Pulsed MIG welding process with metal-cored wires designed specifically for this material. While this combination offers marked improvements over the speeds and performance of solid wire, it’s also slower than pairing metal-cored wires with a power source offering an optimized Pulsed MIG/MAG process designed for welding galvanized steel.

Metal-cored wires are a type of tubular wire consisting of a metal sheath filled with metallic powders, alloys and arc stabilizers. As opposed to solid wire, metal-cored wires carry higher current densities (at equivalent amperage settings), making it possible to put more weld metal in a joint in less time during the welding process. Because of the fast travel speeds these type of wires offer, they are often chosen for robotic welding applications like those found in automotive manufacturing.

Recent advancements in metal-cored wires, specifically those carrying the AWS classification E70C-GS, provide significant advantages when welding hot-dipped galvanized steel. These wires feature formulations that allow them to weld with a direct current electrode negative (DCEN) or straight polarity.

Operating in straight polarity offers two distinct advantages when welding this material with metal-cored wire. These include:

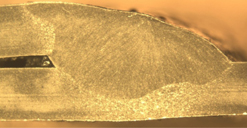

• A softer arc penetration that prevents burn-through on thinner gauged material and creates an improved penetration profile. (See Figure 1)

• Sufficient arc energy to vaporize the galvanized zinc coating. This action allows enough time for zinc vapors to outgas from the weld pool to minimize porosity in the subsurface of the weld and on its surface drastically.

created with metal-cored wire and Pulsed

MIG/MAG optimized for galvanized material

Like other metal-cored wires, these metal-cored wires also feature arc stabilizers that help improve metal transfer from the wire to the weld, effectively reducing spatter and necessitating little to no post-weld cleaning that could slow down the overall throughput. The manner in which the wires also mitigate zinc vaporization further prevents arc instability that could lead to poor weld quality, rework or rejected parts.

The Pulsed MIG waveform process optimizes these results by aptly controlling the deposition of the wire across the arc at controlled intervals in the welding cycle. The power source switches welding output rapidly between a high peak current to a low background current to create the pulsing effect. The peak current then pinches off spray-transfer droplets and propels them toward the work piece. The combination of this action, along with the formulation of specific E70C-GS metal-cored wires for galvanized steels helps control the pace at which the weld pool freezes, allowing the zinc vapors to escape more readily. In addition, the Pulsed MIG process also generates lower heat input than the standard CV process used to weld with solid wire, making it less likely to burn through the thinner material.

Other benefits of combining metal-cored wires for galvanized steels with the Pulsed MIG process include:

• Improved T-joint and downhill welding.

• A fine ball transfer that creates a broad arc pattern and wide weld bead with good gap-bridging abilities.

• The ability to weld a range of material thicknesses (1.2 to 4.0 millimeters)

• The ability to weld in multiple positions.

The combination of the two technologies has also proven beneficial in addressing the variable surface thickness of hot-dipped galvanized steels, adjusting for that unevenness and still providing quality welds that are strong, yet ductile — additional features that can benefit the automotive industry as manufacturers continue to seek a means to improve their welding operations and gain a competitive edge.

Related Articles:

Galvanized Steel Paired with Metal-Cored Wire Offers Benefits in Automotive Manufacturing