The Consequences and Control of Hydrogen in the Welding Process

Despite its abundance in the earth and atmosphere, and its contributing benefits as an energy source — natural fuels, for example — when hydrogen presents itself in the welding process, it can cause significant quality and productivity issues. This highly combustible element (signified by H on the periodic table and the atomic number 1) can cause stress in the microstructure of the base material and weld metal, leading to hydrogen-induced cracking. This cracking (also called cold, underbead or delayed cracking) is a rejectable defect that requires repairs that are often costly. More importantly, hydrogen-induced cracking is dangerous, as weld failures from this defect can lead to catastrophic events if they are not recognized before a part enters service.

by H on the periodic table and the atomic number 1)

adversely affects the microstructure of a weld and,

as a result, can easily lead to hydrogen-induced

cracking. There are methods, however, for reducing

this opportunity.

For manufacturers, fabricators or contractors welding on steel used in critical applications — such as structural steel erection, transmission pipelines, the offshore industry, process piping and others — that require x-ray and/or code quality welds, it’s absolutely essential to control the presence of hydrogen throughout the welding process. It’s a best practice for non-critical applications as well; however, the materials being used in these jobs are not always as susceptible to hydrogen-induced cracking and so the issue may be of lesser concern.

To help better understand the impact of hydrogen in the welding process, it’s important to take a deeper look at the consequences associated with its presence and the methods for controlling this element from the start to the finish of the welding process.

Entering the weld pool

The means by which hydrogen can enter the weld pool vary. Typically, hydrogen picked up during the welding process is present in the form of moisture. This moisture comes from humidity in the atmosphere or it can come from the base material in the form of mill scale, grease, oils, paint or other coatings.

Welding filler metals can also be a source of hydrogen in the welding process. The dry chemicals and metal powders used as fill for tubular wires (composite metal-cored and flux-cored or FCAW wires), as well as the flux coatings on shielded metal arc welding (SMAW) electrodes can be susceptible to moisture pickup that introduces hydrogen to the weld.

Hydrogen-induced cracking — how and where does it happen?

Hydrogen is quite mobile when introduced into the liquid weld pool, especially at elevated temperatures, and much of it is able to diffuse out into the atmosphere. Once the weld has cooled, it is more difficult for hydrogen to escape and the element tends to collect in the grain boundaries and the heat affected zone (HAZ) — the area of base metal just beyond the weld deposit. Over time, hydrogen collects in these areas and builds stress that, in some cases, is high enough that hydrogen-induced cracking occurs. Hydrogen-induced cracking can also occur in the weld metal itself and when it does, it is typically transverse to the weld direction.

Materials with higher carbon and/or alloy levels are especially prone to hydrogen-induced cracking. This susceptibility comes from the presence of and propensity toward a more brittle or crack sensitive microstructure called martensite.

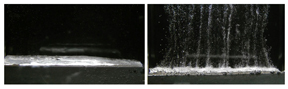

metal-cored wire and the image on the right is a weld completed

with a cellulosic (non-low-hydrogen) SMAW electrode. Both welds

were completed following the same procedures and submerged

in mineral oil to show the presence of hydrogen diffusing from the welds.

Martensite can occur naturally during the steel forming process, resulting from the heating and cooling of the molten metal. It can also develop during the welding process. The heat of the welding process can change the microstructure of the base material, especially in the HAZ, making it more brittle (or creating martensite), especially if the weld has cooled rapidly. As carbon and/or alloy content increase the chance of forming martinsite also increases.

Typically, hydrogen-induced cracking occurs at temperatures below 600 degrees Fahrenheit (more commonly around or below 300 degrees Fahrenheit) and within 48 hours of completing the weld. In some cases, it can occur as much a week after welding.

In applications with greater contributing factors — highly restrained joints; high levels of hydrogen; or rapid cooling after weld completion — hydrogen-induced cracking can occur much sooner, even immediately.

Methods to control hydrogen

To avoid the consequences of hydrogen-induced cracking — rework, increased labor and material costs, lost productivity and quality issues — it is important to implement methods of controlling hydrogen in the welding process. It’s even more important to protect against this weld defect to prevent dangerous product failures. Here are five key ways.

1. Minimize joint stress: Highly restrained joints can contribute to hydrogen-induced cracking, not because they are more prone to accumulating hydrogen, but rather because they are already naturally under stress. That stress can contribute to the other stresses created by the presence of hydrogen in the weld and lead to cracking. When possible, designing a joint to minimize stress can be helpful (in conjunction with good welding practices that reduce hydrogen) to reducing hydrogen-induced cracking.

2. Use proper pre- and post-weld heating: Pre-heating and post-weld heat treating (PWHT) are both critical means to minimizing hydrogen-induced cracking. Pre-heating provides two key benefits. First, it can remove residual moisture in the base material, which would otherwise be a source of hydrogen. Secondly, it helps to slow down the cooling rate after the weld is completed, which allows more time for the hydrogen to diffuse out of the weld and reduces the formation of the crack-sensitive martensite. For example, a base material that is pre-heated to 500 degrees Fahrenheit will take much longer to cool than a base material that is an ambient temperature of 70 degrees Fahrenheit.

Similarly, elevating the temperature of the weldments after welding can help any hydrogen that is present to diffuse more readily.

Induction heating, in some applications, can provide optimal hydrogen diffusion and uniform heating throughout the part. It is also safer than heating with an open flame (the induction heating coils do not actually get hot) and it provides a faster time-to-temperature than other heating methods.

3. Select the appropriate filler metal: Filler metal manufacturers typically offer tubular wire (metal-cored and flux cored wires) and SMAW electrodes in low hydrogen varieties. There is an optional designation for diffusible hydrogen that can be included in the American Welding Society (AWS) classification. Filler metals featuring a H4 or H8 designators have passed tests proving that they deposit weld metal containing low levels of diffusible hydrogen. For example, filler metals with H4 designation consistently produce weld metal deposits containing less that 4ml of hydrogen per 100g of deposited weld metal (H8 = 8ml). SMAW electrodes can have an additional designation “R” that means that the electrode is resistant to absorbing moisture.

Solid wires also offer low hydrogen levels. Because of the way these filler metals are manufactured (they have no fill material), they are less susceptible to moisture pickup and are therefore less susceptible to hydrogen-induced cracking. Note, however, the hydrogen designation is optional in the AWS classification and typically not included for solid wires.

4. Store and handle filler metals properly: It is important to store filler metals in a dry area and keep them in their original packaging until they are ready for use, not only to reduce the opportunity for hydrogen pickup, but also to prevent them from gathering other contaminants such as dirt or debris.

The storage area should also be similar in temperature to the environment in which the welding will take place. Storing the filler metal in a cold area and moving it to a hot one can lead to condensation, increasing the chance of hydrogen being introduced into the weld. If a storage area of similar temperature is not available, allowing the filler metal to acclimate to the temperature of the welding environment before opening the package can help minimize the risk of condensation and subsequently, cracking.

5. Consider the filler metal packaging: Filler metal packaging that is heat- and/or vacuum-sealed is most likely to block moisture and hydrogen from the product. Tubular and solid wires are often packaged in this style of bag. SMAW electrodes are also available in plastic resealable packaging that can help resist moisture. It is important, however, to place open packages of stick electrodes in a designated oven after they have been opened to prevent them from accumulating moisture.

The introduction of these methods into the welding process is the first and best way to control hydrogen in the welding process. These steps can help reduce the risk of cracking that leads to costly rework, downtime, increased labor needs, poor productivity and most importantly, product failure. Too, knowing the means by which hydrogen can enter the weld is a good defense against potential problems.