Metal-Cored Wire Saves Manufacturer $365,000 Annually

When Taylor Machine Works was founded as a family-owned automotive and repair business in Louisville, Mississippi in 1927, the company motto was painted on the building’s sign: “We engineer and build what you need.” More than 90 years later, the company produces much bigger machines, but that motto still holds true.

“Taylor’s name and reputation were built on customization. Between 40 and 50 percent of what we build has engineering or research and development applied to it in some way,” says Matt Hillyer, director of engineering for Taylor Machine Works. “The forklifts and equipment we design and build are integral to our customers’ needs. And answering those needs is all about knowing the customer very closely, and them knowing us.”

“They can count on us to have a piece of equipment that is going to be in operation for the long haul, and it will serve the needs of their business,” Hillyer says. Along with the commitment to customization, the company has stayed consistent in many other ways through the years. The same family that started Taylor Machine Works is still at the helm today, with the third and fourth generations involved. The company also remains in Louisville — population about 6,300 — because that’s where its roots are. That legacy lets customers know they can “Depend on Big Red” and the machines Taylor produces.

The Taylor legacy also includes a commitment to innovation and improvement. Founder W.A. Taylor, Sr., produced his first conventional timber skidder in 1937, a pioneering machine that was later developed into a mobile skidder and loader. Product development and innovation is still a constant.

Today, Taylor is a leading manufacturing of more than 85 models of powered industrial trucks such as forklifts and material handling equipment for customers across North America and internationally in the shipping, marina, steel and aluminum industries. Many of these machines are highly customized to meet specific customer needs.

As part of the drive for innovation, Taylor is always looking for technologies that help the company improve. A recent change to the welding filler metal used for equipment fabrication at Taylor significantly increased productivity and decreased costs — allowing the company to be even more nimble in responding to customers and meeting deadlines.

“The benefits were immediate,” says Steve Nazary, quality assurance supervisor. “It has really improved our quality and our productivity by using Hobart wire.”

Equipment durability and dependability are also key drivers for Taylor’s customers. If a customer is a small lumber mill with only three pieces of equipment, that business can’t afford to have one machine go down for repairs.

impact on productivity and weld quality when using the wires

on T-1 steel, thanks to faster speeds, higher deposition rates

and less post-weld cleaning.

Welding heavy-duty products

Taylor’s production is driven by market demand. When the market is up and customers need equipment, they don’t want to wait for development or research. Taylor works to respond quickly with a solution for customers.

“That’s a large part of their ability to produce and run the business,” Hillyer says. “So, we need to make advanced, innovative products that are also simple, durable, easy to work on, and provide constant uptime.”

Taylor produced roughly 750 pieces of rolling stock in 2017 that went out the door to customers. Welding is a critical part of that manufacturing operation.

“Welding technology and filler metals are key to us providing a quality product,” Hillyer says. “It has to stand the test of the customer’s application and the test of time.”

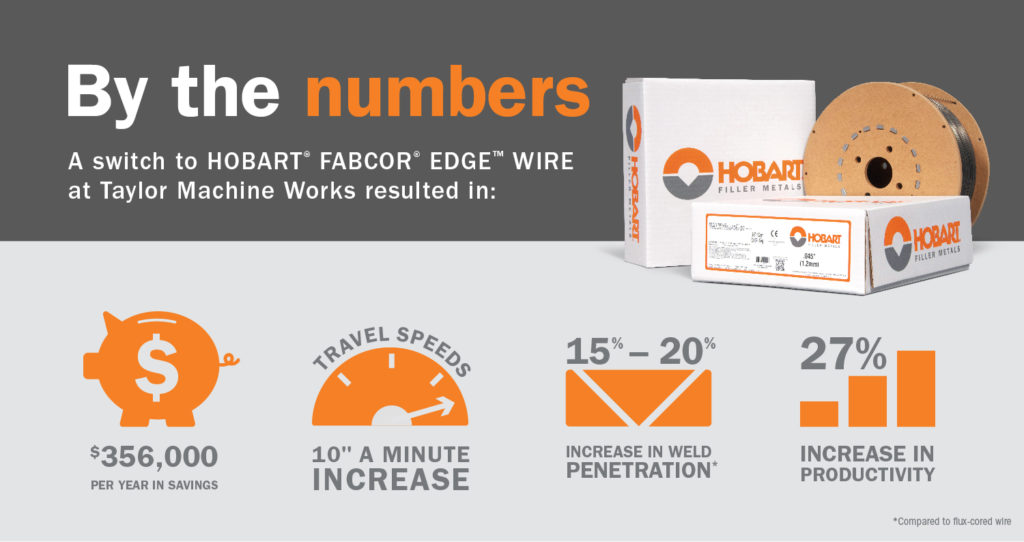

Metal-cored wire saves $365,000 a year

The company previously used flux-cored wire in its welding operation but made a filler metal change after Taylor’s welding distributor suggested that Hobart® FabCOR® Edge™ and FabCOR Edge D2 metal-cored wires could help improve welding performance. In a test of the metal-cored wires, Taylor saw an immediate impact on productivity and weld quality when using the wires on T-1 steel, thanks to faster speeds, higher deposition rates and less post-weld cleaning.

“It increased our speed probably 10 inches a minute,” Nazary says.

Taylor has since standardized to the 1/16-inch FabCOR Edge wire for all its welding applications on materials more than 1/2-inch thick, including mild steels and high-strength steels with tensile strength of 70,000 pounds. They use the 1/16-inch wire to weld metals up to 5-inches thick. When working with materials less than 1/2-inch thick, the shop uses .035-inch Hobart solid wire.

“We did a study when we first changed the wire and we came up with $365,000 worth of savings per year,” Nazary says. “That’s huge. The more Hobart wire we use, the more cost savings will add up.”

In addition to the filler metal change, Taylor is converting its welding fleet to Miller® XMT® 450 multiprocess welders. These reliable, compact XMT 450 welders reduce the amount of space the machines take up in the shop.

“The XMTs are really smooth and the wire rolls through really smoothly. You can adjust welds perfectly,” says Adam Eubanks, a fitter welder with Taylor. “It puts a better-quality weld down, and it just makes it easier for welders.”

Productivity gains of 27 percent

The substantial annual cost savings for Taylor are due in part to the significant productivity increases from the Hobart FabCOR Edge wire. It welds faster and delivers better penetration — about 15 to 20 percent greater weld penetration compared to flux-cored wire — so more filler metal can be deposited in less time. That means more equipment can be completed and out the door faster for customers.

“By switching to Hobart metal-cored wire, we increased productivity 27 percent,” Nazary says. “That’s a big improvement. That’s a big cost savings.”

The metal-cored wire also delivers easy weldability.

“I like it because it burns a little hotter, and most of what we weld is thicker material. It’s a more efficient wire,” says Eubanks. “It puts a better weld down, even on material that’s not perfectly cleaned.”

Reduced spatter and less cleanup

Because the FabCOR Edge wire doesn’t produce a slag on the weld bead, it greatly reduces the time and money Taylor spends on interpass and post-weld cleanup. There is no need for welders to remove any slag between weld passes.

metal-cored, they love it,” Kurt Glenn, fitter welder, says of training new welders.

“It’s a quicker, better and cleaner job with the metal-cored wire.”

Previously, the operators used a chipper hammer to remove slag and spatter between passes, which added time and hassle to their process.

“Once we got the metal-cored wire, it eliminated that,” says Kurt Glenn, a fitter welder and robot operator. “There was no more spatter or slag. It was a clean weld. It stacked a lot better.”

In addition to saving time in weld cleaning between passes, it also saves time in cleaning up around the shop and money in equipment maintenance.

“We quit buying air chippers and we do less maintenance on the chippers now,” Nazary says. “We quit having to sweep the floor as often, and there is less cleanup in the paint shop. These were all immediate benefits of using the Hobart wire.”

The reduced spatter of the metal-cored wire also makes cleaning and painting the parts easier and faster, allowing Taylor to get parts from the production cell to the paint cell much faster.

Better looking, high-quality welds

The aesthetics of the finished welds on the equipment Taylor produces is another important consideration. The company conducts visual weld checks and sometimes dye penetrant checks on restricted weld joints.

“The welds look smoother. They have a lot better eye appeal and that’s very important,” Nazary says. “We had a lot less cracking issues with the wire, also. I have more people pass the test with this wire than I did with a flux-cored wire.”

The wire is more forgiving, so it’s easier for even less experienced welders to produce a quality weld.

“Once they get familiar with it and you show them the correct way to weld with metal-cored, they love it,” Glenn says of training new welders. “It’s a quicker, better and cleaner job with the metal-cored wire.”

Save time and money with metal-cored wire

The forklifts and material handling equipment built by Taylor Machine Works must be tough and durable enough to take on heavy loads. The filler metal used by Taylor to fabricate its equipment must match that toughness.

“The weld filler metal strength is imperative. We need filler metal to be highly durable, high strength and handle stresses and high forces,” Hillyer says. “We look to our suppliers like Hobart to provide us with the right technology.”

The conversion to FabCOR Edge wire has significantly improved productivity and saves Taylor a significant amount of money — while helping the company produce better-looking, higher-quality welds.

“I have not seen anything that beats the Hobart Edge wires, and Hobart right now for us is the best welding wire we can use,” Nazary says.