Hardfacing Can Keep Equipment In Service Longer

Equipment wears down and sometimes breaks — it’s a fact of doing business. But when it happens unexpectedly, it can lead to unnecessary downtime, costs and frustration. Hardfacing is one way to quickly, efficiently and cost-effectively make equipment more wear-resistant. It can also help reduce the number of spare parts to inventory and result in longer equipment life.

Hardfacing bonds a filler metal to the equipment’s base metal in order to obtain specific wear dimensions and/or properties, such as impact or abrasion resistance. The process can return worn parts on older equipment to nearly new condition for 25 to 75 percent less than the cost of replacement parts — and it can lengthen the life of surfaced parts by up to 300 percent compared to non-surfaced parts, especially on newer equipment.

make equipment more wear-resistant. It can also help reduce

the number of spare parts to inventory and result in longer

equipment life.

A few basic guidelines can help provide the best results from the hardfacing process, while also minimizing the risk of parts, such as buckets or teeth, from cracking or breaking.

Hardfacing techniques

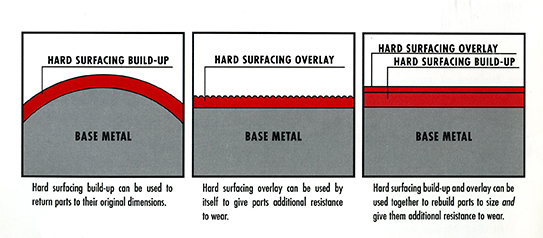

There are several types of hardfacing, so it’s important to first determine the needs for a specific piece of equipment. Hardfacing techniques include:

Build-up — placing layers of welds on top of each other to return older equipment to original dimensions after it’s been worn by impact or abrasion

Overlay — adding a weld layer that protects the equipment against metal loss

Combination — using both techniques to extend equipment life, which can be used repeatedly as long as the part or equipment remains sound

Base material considerations

The equipment’s base material is an important consideration when choosing a hardfacing filler metal. Carbon or low-alloy steels are probably the most commonly hardfaced materials. Keep in mind that materials containing higher amounts of carbon and/or alloy content tend to be more brittle and often require pre- or post-heat, or stress relieving to prevent cracking, as do thicker base materials.

Austenitic manganese steels are used for abrasion and impact properties and can also be hardfaced, but these too can become brittle during the welding process. Austenitic manganese steels typically do not require preheat- unless the temperature of the part is less than 50 degrees Fahrenheit to remove or “sweat out” excess moisture within the steel. During hardfacing, the base metal temperature should remain under 500 degrees Fahrenheit. Exceeding this for an extended period of time increases the steel’s brittleness and it starts to lose its abrasion resistance; austenitic manganese steels with higher carbon and lower manganese content accelerate this time/temperature reaction.

Identifying the base material can be done with a magnet test — low-alloy and carbon steel are magnetic, while austenitic manganese steel is not. Watch out for austenitic manganese that has been work-hardened, as it can develop a slight magnetism to it that can be mistaken for carbon steel or low-alloy steel. Spark tests can also be completed to determine base metal type and may require grinding on the part. For example, a spark test resulting in a longer yellow spark stream indicates low carbon mild steel, while a bright yellow and white spark stream with minor branching indicates high manganese steel. Consult a spark profile chart from a trusted filler metal manufacturer to help identify base metals.

For all materials, it is important to pre-clean the part prior to the hardfacing process. Wipe the part free of all contaminants and, if necessary, remove old hardfacing layers, as well as cracks, via carbon arc or plasma gouging, or by grinding.

the needs for a specific piece of equipment. This figure explains the three

key options.

Equipment wear factors

The type of wear the equipment encounters is another important factor to determine the best hardfacing filler metal. Abrasion accounts for roughly 55 to 60 percent of equipment wear, and there are several types:

Low-stress scratching, the least severe form, results when the metal slowly wears away due to scouring action. Hardfacing with carbide or chrome-carbide filler metals best protects against this type of wear.

High-stress grinding is caused by repeated crushing and grinding of materials against the equipment. The best filler metals for this type are those containing austenitic manganese, martensitic irons or titanium carbides.

Gouging occurs when large objects, such as rocks, press against the equipment. Filler metals containing high carbide alloys and supported by austenitic manganese provide good impact resistance to protect against gouging.

In addition to abrasion, other types of common equipment wear include:

Impact wear, which results from a compressive load placing high mechanical stress on the equipment. Use austenitic manganese steel filler metals (11 to 20 percent Mn) for good work hardening characteristics.

Adhesive wear, also called metal-to-metal wear, occurs from non-lubricated friction of metal parts against one another. A martensitic hardfacing alloy is recommended, but austenitic manganese or cobalt-based alloys also work.

Secondary types of wear include:

High-temperature, also called thermal fatigue or fire cracking, which results when equipment repeatedly encounters high temperatures followed by rapid cooling. This can leave deep cracks in the base material. A non-ferrous alloy is generally best to protect steel surfaces subject to temperatures above 1200 degrees Fahrenheit. Below that range, use a filler metal containing chromium-carbide or a martensitic steel filler metal.

Corrosive wear should be dealt with separately. Most filler metals provide some rust protection. Consult an equipment or filler metal manufacturer to obtain recommendations.

Desired surface finish

Filler metals for hardfacing range from easy to difficult to grind, so the type of surface finish required is another consideration in making the filler metal choice.

When a smooth surface is necessary, measure the time and cost of grinding versus using a filler metal that has slightly less wear resistance, but provides a smooth finish. Another option is a filler metal that can be heat-treated to soften it for machining, and then brought back to the hardness necessary to protect equipment.

If stress relief checks are acceptable on the finish, consider a carbide alloy designed to be crack sensitive. These small cracks help prevent spalling, but do not adversely affect or weaken the wear characteristics provided by the hardfacing filler metal.

The lower the percentage of carbides in the filler metal, the less likely stress relief checks will occur. However, a lower carbide percentage will also provide less abrasion resistance.

Thoughts on repair

Even with preventive maintenance like hardfacing, equipment can still break. Keep in mind these filler metal considerations to handle equipment repairs.

-The chemistry of some filler metals allow them to be used for both joining a broken part and hardfacing on austenitic manganese. Filler metals with higher amounts of manganese can be used for both purposes because they are more ductile.

-Filler metals with higher carbon content have increased hardenability and therefore should not be used for joining, because this increases the brittleness of the weld and makes it more likely to crack or break.

-When welding on austenitic manganese steel, it’s sometimes recommended to remove a 1/8-inch layer of base metal — which can be the work-hardened layer — to help avoid under-bead cracking.

-Low-alloy steel has a higher strength, so it requires the use of a higher strength filler metal to obtain the best results when repairing a broken part.