Gaining Benefits with Low Hydrogen Filler Metals

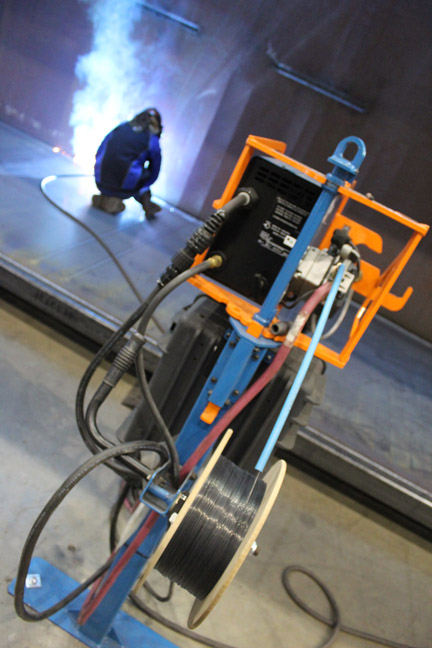

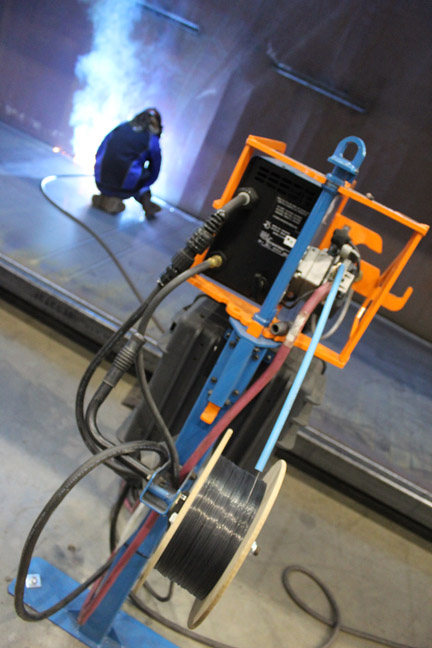

Choosing the right filler metal is as much a matter of matching the chemical and mechanical properties of the material being welded as it is considering the available equipment, operator skill set and the service conditions the finished product will encounter. The climate where the welding takes place is also a factor. In certain industries — including pipeline, offshore fabrication, and heavy equipment manufacturing — where increasingly higher strength materials are being used for service in extreme climates and/or where welding takes place in a very hot or cold environment, using a filler metal with low hydrogen levels is imperative. High-strength low alloy steels, typically those above 70 ksi, are especially prone to hydrogen-induced cracking. Using low hydrogen filler metals, along with implementing the appropriate pre-/interpass and/or post-weld heat treatments and minimizing residual stresses in joint design, can help mitigate that risk.

Low hydrogen filler metals are those classified with less than 4 ml of diffusible hydrogen per 100 g of weldment. The most common for high-strength steel applications are shielded metal arc welding (SMAW) electrodes, gas metal arc welding (GMAW) wires, gas-shielded flux-cored arc welding (FCAW) wires and metal-cored arc welding (MCAW) wires with an H4 designator (for example, American Welding Society [AWS] E80C-Ni1 H4).

The dangers of hydrogen

Hydrogen is unavoidable in the welding process. In addition to being present in filler metals, hydrogen can also enter the weld pool from the atmosphere and the base material.

70 ksi, are especially prone to hydrogen-induced

cracking. Using low hydrogen filler metals, along

with implementing the appropriate pre- and/or

post-weld heat treatments and minimizing residual

stresses in joint design, can help mitigate that risk.

In exceptionally cold environments, the opportunity for hydrogen to cause problems is especially concerning. The critical cooling rate of the weld is faster in colder temperatures, resulting in hydrogen become trapped in the completed weld more readily. The increased presence of hydrogen in hot, humid environments is also a factor to consider; the more moisture that is in the air, the greater the chance of hydrogen entering the weld pool. The action by which hydrogen-induced cracking occurs is fundamentally the same no matter how it enters the weld pool.

As a highly mobile element, hydrogen is able to diffuse into the atmosphere when the weld pool is still at an elevated temperature. Upon the weld cooling, however, it becomes more difficult to escape, resulting in the hydrogen becoming trapped in the weld and migrating to the grain boundaries and the heat affected zone (HAZ). When enough hydrogen collects in the weld, and the right amount of stress builds up in a crack sensitive microstructure, then a cracking can occur. Hydrogen induced cracking typically occurs at temperatures below 600 degrees Fahrenheit (commonly around 300 degrees Fahrenheit or below) and appears within a day or two of completing the weld. It is especially prevalent in the high-strength low alloy steels because of the presence of martensite, a more brittle microstructure that naturally occurs in steel formation and that can also result from rapid cooling after the welding process.

Low hydrogen filler metal options

Using filler metals with low hydrogen designations helps minimize one source of hydrogen in the welding process. In today’s marketplace, there are several options available for welding high-strength steels, each with their own characteristics that can also benefit the welding process.

SMAW electrodes featuring an 18 classification are a good choice for low hydrogen applications that require portability. These include AWS E7018, E8018 and E9018, which all include a H4 designation. These products, in addition to offering low hydrogen levels, also have a tendency to be user-friendly. They have a forgiving arc and low spatter levels and offer good penetration.

Some low hydrogen SMAW electrodes may feature R designators (for example, E7018 H4R), which indicate this product meets additional moisture resistant requirements, making it even less prone to picking up hydrogen, which could result in cracking. To obtain this designation, the SMAW electrode must have successfully undergone testing that proves it is moisture resistant (within a specified range) after being exposed to 80 degree Fahrenheit temperature and 80 percent relative humidity for nine hours.

While each with its own benefits and limitations, solid, flux-cored and metal-cored wires with low hydrogen levels can also benefit high-strength welding applications that are more crack sensitive. Choosing among these options depends on how low of hydrogen levels are desired or required for the job, as well as the general welding characteristics being sought.

Solid wires featuring an AWS E70S-6 classification, as well as metal-cored wires such as AWS E70C-6 H4 products are good options to reduce the opportunity for hydrogen-induced cracking. Metal-cored wires with an AWS E80C-Ni1 H4 classification are also good for slightly higher strength properties. Solid wires tend to resist hydrogen pick quite well as it is difficult for moisture to penetrate the solid steel structure. The copper coating on these wires also offers some protection against moisture. Metal-cored wires tend to be non-hygroscopic and therefore, provide good protection against moisture absorption and hydrogen pickup.

of hydrogen in the welding process. In today’s marketplace, there are several

options available for welding high-strength steels, each with their own

characteristics that can also benefit the welding process.

While similar in terms of low hydrogen levels and moisture resistance, choosing between solid wires or metal-cored wires becomes largely a matter of preference. Solid wires are well known and relatively widely accepted in the industry for high-strength applications; however, some welding operations prefer to use of metal-cored wires to gain faster travel speeds and higher deposition rates. Metal-cored wires have a tendency to bridge gaps better and are also capable of minimizing pre- and post-weld activities such as grinding due to the ability to weld through mill scale and the production of low spatter levels. Both solid wires and metal-cored wires, due to their formulation, offer smooth welding characteristics, which is a benefit that can be slightly more challenging in flux-cored wires offering low hydrogen levels.

Low hydrogen SMAW electrodes require additional care. These must be held in a holding oven at the temperatures recommended by the filler metal manufacturer after being opened.

Maintaining good weldability in low hydrogen flux-cored wires can be a bit of a balancing act for filler metal manufacturers. These wires require the addition of fluoride, which acts like a scavenger to pull hydrogen from the weld pool. The fluoride can sometimes adversely affect the welding characteristics, making the arc flutter or be slightly more difficult to control. Fortunately, formulations have improved drastically over the years, with many smooth operating flux-cored wires being made available in the marketplace. Flux-cored wires for low hydrogen applications can range greatly in strength, with options from 70 ksi (AWS E71T-1MJ H4) up to 128 ksi (AWS E111T1-K3MJ H4) for crack-sensitive quenched and tempered steels or for offshore structural fabrication that will be subject to temperature extremes.

In addition to standard low hydrogen flux-cored and metal-cored wires, there have also been advancements in filler metal manufacturing that can help reduce the opportunity for hydrogen-induced cracking. Seamless wires of both varieties are becoming a more popular option to mitigate cracking risks. These wires undergo a proprietary manufacturing process that eliminates the need to fold and draw the product as with standard tubular wires; they are filled with flux in a single, seamless tube via vibration. In addition to being low hydrogen (the products have an H4 designation), the lack of seam offers increased resistance to moisture pickup, as does these wires’ copper coating. There is no place for the moisture to accumulate on the surface of the wire and, therefore, less opportunity for hydrogen to be introduced into the weld pool. As a result, these wires are very well suited for welding in challenging climates.

Storage considerations

Proper filler metal storage is always important, and caring for low hydrogen SMAW electrodes and wires are no exception. Low hydrogen filler metals typically ship from the filler manufacturer in a hermetically sealed package to protect against moisture pickup and damage. Welding operators should always take care to keep the filler metal packaging intact until ready for use, preferably in a dry storage area, and use clean gloves when handling the product.

Some job codes may also dictate how long a package of low hydrogen filler metals can be open and still be used. In the case of SMAW electrodes, the number of times the filler metals can be recondition may also be specified. Welding operators should always consult the specifications and codes for the given low hydrogen filler metal to gain the best results — specifically minimizing cracking that could lead to costly downtime and rework.