Jun 19, 2014

New Seamless Wires Offer Extreme Resistance to Moisture Pickup, Minimize Cracking

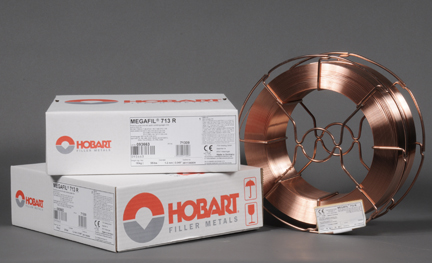

TROY, Ohio. June 18, 2014 — Addressing common industry concerns with weld cracking, Hobart Brothers Company has introduced new seamless flux-cored and metal-cored wires designed to offer extreme resistance to moisture pickup and minimize this costly defect. The new Hobart® MEGAFIL® wires also have less than 4 ml of diffusible hydrogen per 100 g of weldment, which further mitigates cracking risks.

Both the flux-cored and metal-cored versions of the MEGAFIL wires feature a copper coating to improve current carrying capabilities and with it, provide excellent weld quality. A proprietary manufacturing process adds to the consistency of the MEGAFIL wires by ensuring a uniform flux filling, while the wires’ uniform shape helps minimize contact tip wear. These properties make the wires a good choice for both semi-automatic and robotic welding applications.

The MEGAFIL wires also offer robust mechanical properties, allowing the welds created with these products to withstand the harshest environments. The wires are designed specifically for use in offshore platform and bridge construction, shipbuilding, and steel and pressure vessel construction, as well as pipe, tube and heavy equipment manufacturing.