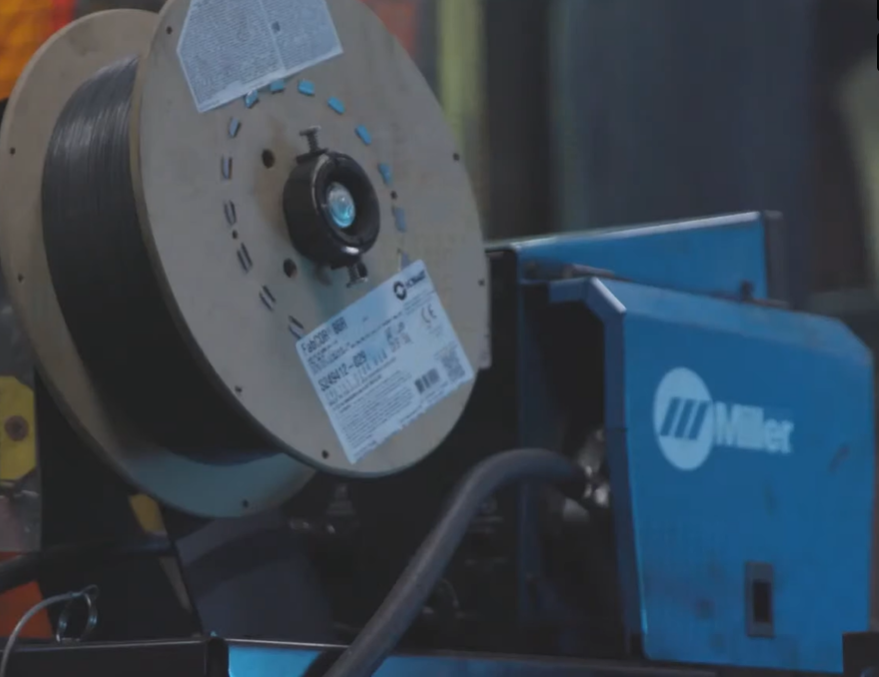

FabCOR® 86R Metal-Cored Wire Improves Weld Penetration

With its previous solid wire, Webster Industries had challenges gaining consistent weld penetration. Switching to metal-cored wire solved the problem. Welds made with FabCOR 86R wire on the company’s welded drag chains and other products pass all of the company’s tests — a critical factor to prevent part failures in the field. The high quality of the wire also helps Webster Industries produce better parts for its customers and has opened up opportunities for generating more work.

Video Transcript

We’ve had some issues over the years with weld penetration and we cannot have any parts failures in the field. With the penetration of the FabCOR 86R wire, we’ve moved away from any issues with that. The parts break the way they’re supposed to, they pass our tests. You can watch it cut a lot deeper than any steel wire that we’ve used, and that way we know we’re getting better welds that are going to hold a lot longer.

It leaves a lot less spatter than any of the other steel core wires, so then that way I don’t spend 15 minutes on every piece cleaning it off. We have not had any customer complaints from the field in terms of wire failure or weld failure. It opens the market for us to be able to produce different products, and it has also helped us by producing better products for our customers, opening the doors for more work.