Part One: Can Metal-Cored Wire Improve Your Productivity?

Today’s companies need better ways to manufacture their products with fewer resources—and without sacrificing quality or productivity. Sometimes the solution lies in implementing leaner business practices, like creating smoother workflow or implementing more effective parts inventory. Other times, the solution lies in obtaining more efficient equipment. Regardless of the solution that works best to streamline your particular operation, one factor is always a consideration for increasing productivity: labor.

Most supervisors and welding engineers agree that labor constitutes more than 80 percent of the cost of a semi-automatic (hand-held) welding operation. In these operations, certain tasks almost always occur: cleaning; applying anti-spatter and tacking parts prior to welding; moving parts into and positioning them within the weld cell; removing spatter and/or slag; grinding the weldments to prepare them for painting, powder coating or similar finishing; and finally, moving the parts to those latter production areas. Many companies consider these activities and their associated labor to be valued-added, meaning they add directly to the successful completion of the welding process.

Interestingly, certain welding technologies have begun to challenge such assumptions; they bring to question whether all of these activities are necessary for the overall throughput of a welding operation or whether they actually hinder productivity by way of unnecessary pre- or post-weld activities. Metal-cored wire is among such technologies, and while it isn’t new (the first metal-cored wire entered the welding scene in the mid-1970s), it has evolved significantly over the years.

This article, the first in a two part series, can help you begin to consider whether metal-cored wire is a viable option to improve your welding productivity.

Understanding the Technology

Like any filler metal (solid or flux-cored wire or stick electrode), metal-cored wire has its own unique characteristics, benefits, limitations and best applications. On the average, this wire costs more per pound than other filler metals, but it has also been shown to yield significant productivity increases that help negate that upfront cost.

First, let’s consider the basics of the technology. Whereas solid welding wire (as its name implies) is solid throughout its entire cross section, metal-cored wire consists of a hollow metal sheath filled with metallic powders, alloys and arc stabilizers. These special formulations create very distinct effects, from lowering oxidation to providing higher impact strengths and/or reducing silicon deposits in the final weld. They also make metal-cored wire especially suitable for welding through mill scale—the fine oxide layer found on ‘hot-rolled’ steels—and other contaminants.

Metal-cored wire uses the spray transfer process, which creates tiny filler metal droplets that deposit in the weld puddle and generates very little to no spatter. Because the current travels through the outside metal sheath, the wire produces a broad, cone-shaped arc, resulting in a wider penetration profile as compared to the more finger-like penetration of solid wire. This arc shape creates a wide, consistent bead profile that bridges gaps easily and accurately without burn-through. The wire’s construction also allows for greater travel speeds, higher deposition rates, and helps minimize porosity and undercut in the final weld. All of these factors increase productivity by allowing welding operators to weld more efficiently, place more weld metal, reduce quality issues, and spend less time cleaning weldments.

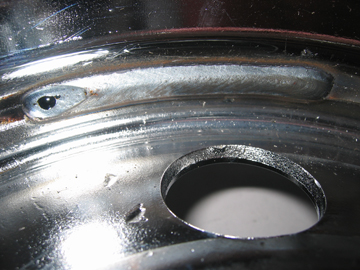

Metal-cored wires are capable of single or multi-pass welding and are suitable for flat, horizontal, vertical down, and even overhead welding using a standard CV (constant voltage) power source. They require high argon shielding gas mixtures, with 75 percent is the minimum requirement. Vertical-up welding is possible with metal-cored wire, however, it requires a power source with pulsing capabilities and will generally be slower than welding, for example, with a flux-cored wire. If you have a high percentage of vertical-up applications in your operation, you’ll need to weigh this factor against metal-cored wire’s other attributes to determine whether it can still increase your welding operation’s productivity. Industries such as heavy equipment manufacturing, rail car fabrication, automotive exhaust, chassis and wheel manufacturing, and food and petrochemical fabrication all have welding applications in which metal-cored wire excels. In part, this is due to the fact that the wires (in addition to the other benefits) can be alloyed for most every type of steel from mild and stainless to low alloy. Many of these industries also frequently weld ¼ inch and thicker material, another application where metal-cored wire offers solid productivity solutions, specifically due to its gap bridging capabilities. Good gap bridging helps minimize burn-through and other weld defects, and reduces the need to re-weld or re-work the rejected parts. As a side note, metal-cored wire is not recommended for welding thin gauge sheet metal or similar materials.

So what does all this mean for your particular welding operation? Perhaps a lot.

What’s the Difference?

Like any technology, metal-cored wire’s attributes mean nothing if they don’t translate into real-life solutions—in this case, better productivity for your total welding operation. Metal-cored wire tends to have faster travel speeds and higher deposition rates than other wires (especially solid wire), but interestingly, the technology offers the greatest productivity potential before and after the welding process as opposed to during it. The question then is, how? Simply stated: in some welding operations, metal-cored wire eliminates certain pre- and post-weld activities (often called non-valued added or compensation activities), allowing labor for those tasks to be used elsewhere in the operation to improve overall productivity.

Activities such as grinding, sand blasting or applying anti-spatter are very typical in many welding operations and it is common to find designated pre-weld areas where these occur. Some companies also have post-weld areas where any additional grinding and/or necessary rework happen. Both of these areas are often considered part of the overall production process, but in fact they can cause bottlenecks in the welding operation that adversely affect the throughput of the fabricated part. Not to mention, the extra labor allocated to these areas costs extra money.

and still create a virtually spatter-free weld.

Consider this scenario: a company uses a solid wire to manufacture Widget A. Prior to welding, the part must be sandblasted and a welding operator needs to apply anti-spatter to the material. These tasks could take, theoretically, 14 minutes to complete. Next, a welding operator spends an additional 16 minutes to fit up or tack the part before welding. While the company cannot eliminate this latter weld preparation, as tacking is essential for the successful welding of the part, it may be able to eliminate the other 14 minutes by using metal-cored wire. Because metal-cored wired effectively welds through mill scale or other minor contaminates and still produces little to no spatter, it often makes activities like grinding, sandblasting and/or anti-spatter application obsolete. In this scenario, the company (by using metal-cored wire) could feasibly reallocate the 14 minutes previously used for pre-weld activities into the weld cell to produce more parts.

Similarly, if this same company requires labor for grinding or chipping spatter and/or reworking defective parts in the post-weld area, it may be able to reallocate labor to other areas by using this type of wire. Since metal-cored wire tends to create little to no spatter and minimizes defects such as undercutting or lack of fusion, such post-weld activities usually aren’t necessary. Additionally, less post-weld activity increases the flow of completed parts to other stages of production, such as painting or coating, to improve overall productivity.

Is There an Opportunity for Your Operation?

It may seem counterintuitive to consider that a welding wire can have such a significant impact on productivity, especially outside the actual weld cell. Still, it may be a beneficial way to streamline your operation, since the benefits described here could allow you to reallocate labor to other parts of your welding operation in order to gain greater overall productivity.

So, how can you determine whether your welding operation is a good candidate for metal-cored wire? Check out ‘Part 2: Can Metal-Cored Wire Improve Your Productivity?’