Structural welding connects our world. Hobart®filler metal connects structures.

Bridges. Skyscrapers. Large structural welding projects demand high-quality welds — which means you need filler metals you can count on:

Hobart® filler metals.

The wrong filler metals can hurt your projects — and your company

Welding is critical in structural projects, so don’t compromise: Get the perfect Hobart welding wire from a wide range of choices. For unique jobs, Hobart can work with you to find a custom filler metal solution — like we did for the San Francisco-Oakland Bay Bridge.

It’s the tie that binds STABILITY + TRUST

Every day, 250,000 vehicles pass over the San Francisco-Oakland Bay Bridge. To ensure safe journeys, engineers responsible for the integrity of the bridge’s structural steel depended on Hobart filler metals — see why.

METAL-CORED WELDING WIRE MAXIMIZES SUCCESS

LeJeune Steel Company uses Hobart metal-cored wire to reduce costs and improve productivity on structural steel projects like the U.S. Bank Stadium in Minneapolis. Learn how.

MOVING FROM STICK ELECTRODES TO SELF-SHIELDED FLUX-CORED WELDING WIRE: PART ONE

Technological advancements could mean that self-shielded flux-cored welding wire is a better choice than stick electrodes for gaining quality and productivity. Learn why.

MOVING FROM STICK ELECTRODES TO SELF-SHIELDED FLUX-CORED WELDING WIRE: PART TWO

Considering self-shielded flux-cored welding wire for more productivity and efficiency? Learn what’s needed to make the move from stick welding.

WELDING WIRE CHANGE SIGNIFICANTLY BOOSTS COMPANY’S PRODUCTIVITY

Learn how a California welding contractor got a 30 percent productivity increase by changing to Hobart gas-shielded and self-shielded welding wires.

FIELD OR SHOP: BEST PROCESSES FOR STRUCTURAL WELDING

The proper welding wire and process for structural steel projects depends on many factors. Learn how to evaluate variables and get great results.

KEEPING WELDING WIRE IN TOP SHAPE ON THE JOBSITE

Filler metals are an investment — not just in the material itself, but also in the success of your welding jobs. Learn the best ways to protect it.

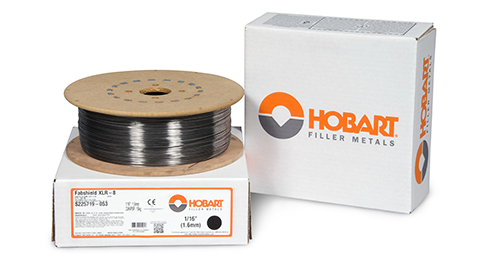

Fabshield®XLR-8

Ideal for structural welding in the field, this self-shielded flux-cored welding wire handles all welding positions at high currents to increase productivity. Low hydrogen weld deposits and high impact strength at low temperatures resist cracking in severe applications.

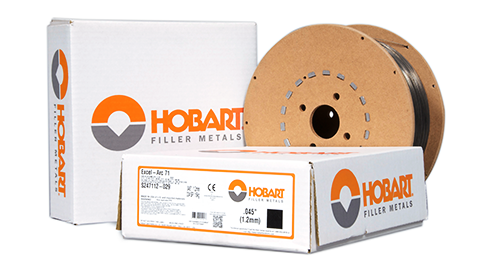

FabCO®Excel-Arc™ 71

This gas-shielded flux-cored welding wire produces minimal spatter and offers easy slag removal for faster cleanup and more productivity. Excellent out-of-position capability, good impact toughness and cracking resistance make it a great choice for shop structural welding.

FabCO®TR-70

This gas-shielded flux-cored welding wire is tolerant to changes in stick-out, making it ideal to compensate for gaps. Flexible amperage and voltage ranges offer easy operation, while high deposition rates improve productivity.

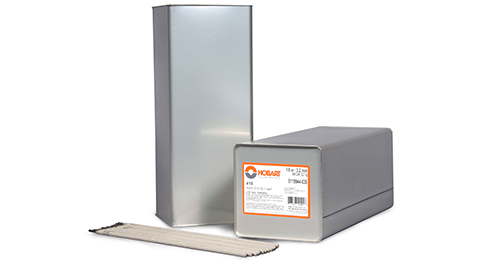

Hobart®418

Low moisture absorption makes this stick electrode a great choice for structural welding in the field. Productivity is enhanced with effortless starts, minimal spatter, stable arcs in all welding positions and easy slag removal.

FabCOR®86R

Higher deoxidation elements allow this metal-cored wire to better penetrate mill scale, reducing pre-weld prep and providing more time to focus on higher productivity.

SubCOR™ EM13K-S

This cored submerged arc welding wire improves deposition rates and offers a broader penetration profile than solid wire at comparable welding parameters for higher productivity and less risk of burn-through.

SDX S2Si-EM12K

The versatility to join a wide range of non-alloyed steels with a variety of fluxes makes this submerged arc solid welding wire an ideal all-purpose product. Its copper coating aids in smooth wire feeding for consistent weld quality.

HN-590

This agglomerated neutral flux provides good deoxidation and weld bead appearance, along with excellent resistance to cracking to minimize rework. Easy slag removal reduces cleanup and lowers the risk of slag inclusions.

SWX 120

High current-carrying capacity allows this agglomerated neutral flux to be used with high-productivity parameters, while a moderate basicity balances good weldability with desirable mechanical properties.