Hobart® 718MC

Brand: HOBART®

AWS: E7018 H4R/E7018-1 H4R (E4818*)

Data Sheet: English

SDS: English (NA), Spanish (NA), French (NA)

Certification: Download PDF

Description

Designed to provide improved deposition rates, bead appearance and operator appeal over other electrodes of the same class when welding in low-temperature environments where low-temperature impacts are important. Excellent moisture resistance, good out-of-position welding capabilities and X-ray quality weld deposit.

Applications

Single and multiple pass, DCEP, AC

Available Products

| Part Number | Diameter (IN) | Diameter (MM) | Package |

|---|---|---|---|

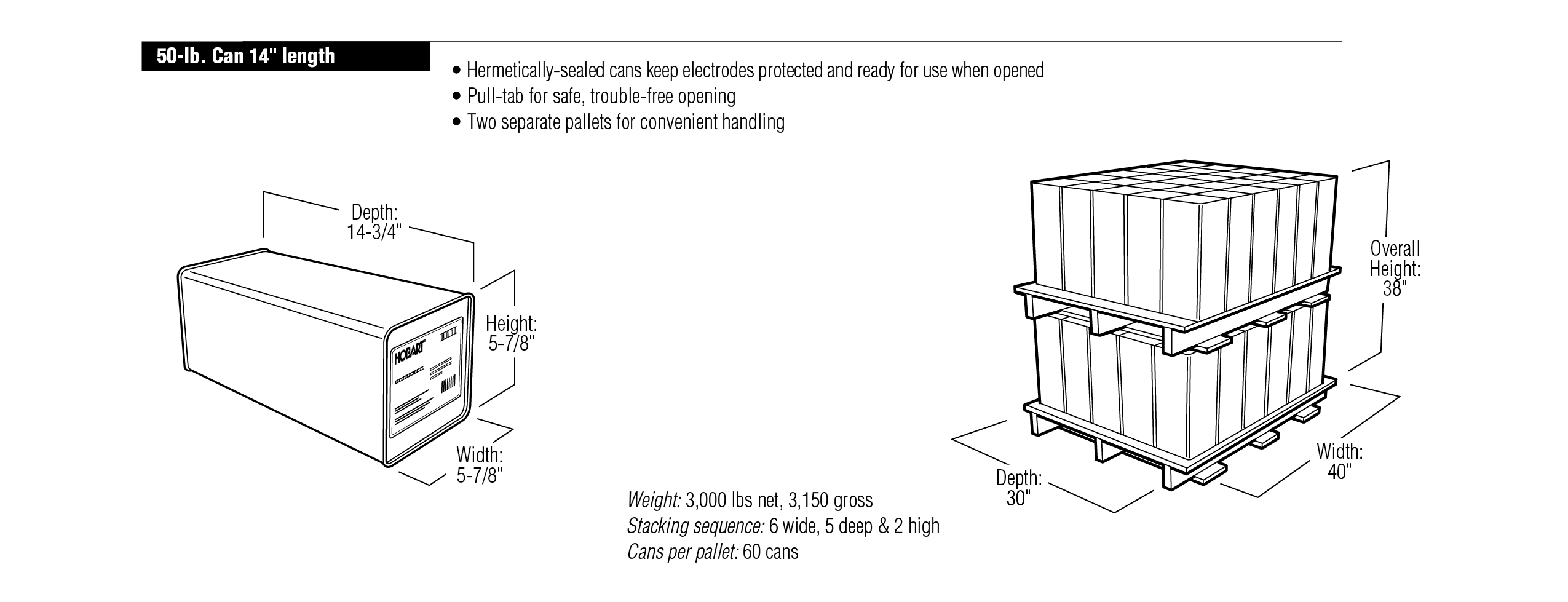

| S115932-035 | 3/32 | 2.4 | 50 Lb (22.7 Kg) Hermetically Sealed Can |

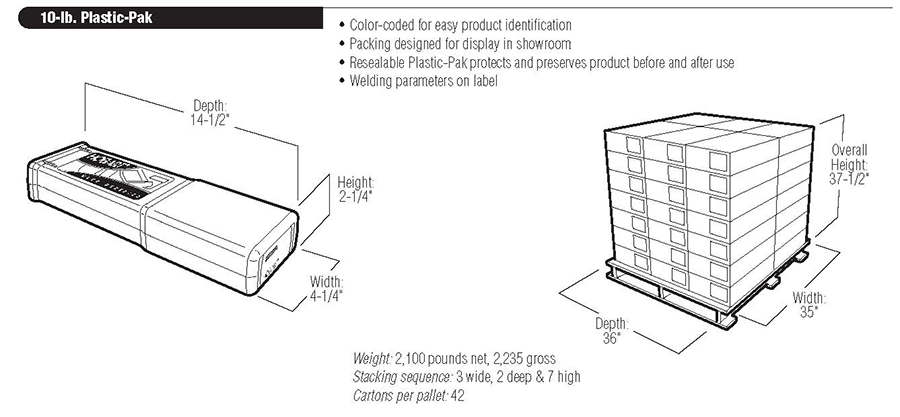

| S115932-089 | 3/32 | 2.4 | 10 Lb (4.5 Kg) Plastic Pak |

| S115944-035 | 1/8 | 3.2 | 50 Lb (22.7 Kg) Hermetically Sealed Can |

| S115944-089 | 1/8 | 3.2 | 10 Lb (4.5 Kg) Plastic Pak |

| S115951-035 | 5/32 | 4 | 50 Lb (22.7 Kg) Hermetically Sealed Can |

| S115951-089 | 5/32 | 4 | 10 Lb (4.5 Kg) Plastic Pak |

Industries

Barge offshore rigs and shipbuilding, boiler code applications, field erections and steel structure, petrochemical and power plants, railroad and locomotive construction, welding of enameling steels, free machining steels, low alloy structural and low, medium or high carbon steels, weldments in low-temperature impacts are important. Construction, Mining, Railcar, Shipbuilding, Offshore, Heavy Equipment, Petrochemical, Power Generation, General FabricationConstruction, Mining, Railcar, Shipbuilding, Offshore, Heavy Equipment, Petrochemical, Power Generation, General Fabrication